Basic Info.

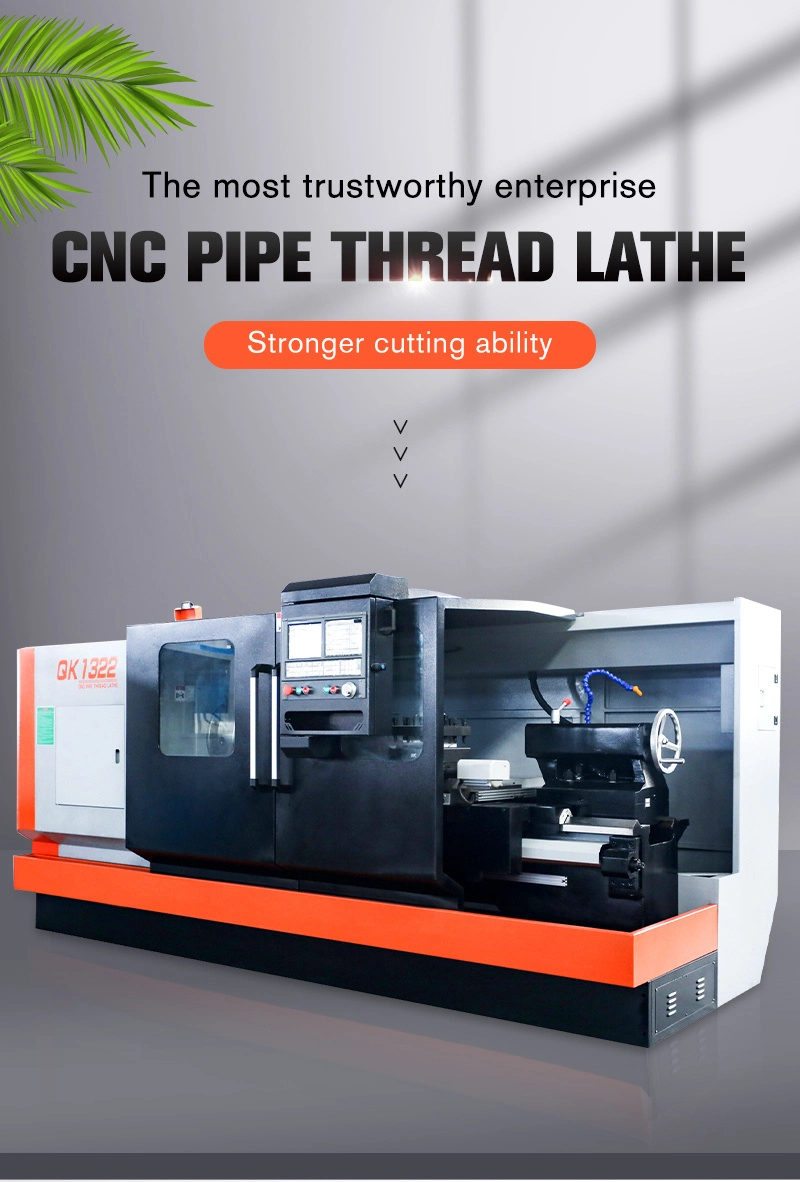

Model NO.

Qk1322

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, CE, ISO 9001

Condition

New

Type

Horizontal

Max. Length of Workpiece (mm)

3000

CNC or Not

CNC

CNC Control System

Fanuc Siemens GSK

Color

Customers′ Requirement

Keyword

Automatic CNC Lathe Machine

Transport Package

Export Packaging

Specification

1850*1850*3300mm

Trademark

Jaos

Origin

China

Product Description

Product Description

1. Two-speed speed change, wide speed regulation range, not only meets the requirements of high-speed thread finishing, but also has high cutting efficiency and low noise.

2. The machine bed is an integral floor structure, which greatly improves the rigidity of the machine tool. The width of the guide rail surface of the bed is wide, and has been quenched and precision ground by super audio frequency.

3. Quenching precision grinding gears and high-quality bearings to ensure low noise and good sound quality of the machine tool.

4. The spindle box adopts powerful external circulation cooling and lubrication, which not only reduces the temperature rise of the spindle, but also maintains the cleanliness and lubrication of the spindle box.

5. The X and Z axes are directly driven by high-precision ball screws and pre-stressed and tightened, and the nut hanger is an integral structure.

6. The large-size 4-station vertical electric turret enables the machine tool to have high processing efficiency and more effectively ensure the precision of the inner hole thread of the fine turning.

1. Two-speed speed change, wide speed regulation range, not only meets the requirements of high-speed thread finishing, but also has high cutting efficiency and low noise.

2. The machine bed is an integral floor structure, which greatly improves the rigidity of the machine tool. The width of the guide rail surface of the bed is wide, and has been quenched and precision ground by super audio frequency.

3. Quenching precision grinding gears and high-quality bearings to ensure low noise and good sound quality of the machine tool.

4. The spindle box adopts powerful external circulation cooling and lubrication, which not only reduces the temperature rise of the spindle, but also maintains the cleanliness and lubrication of the spindle box.

5. The X and Z axes are directly driven by high-precision ball screws and pre-stressed and tightened, and the nut hanger is an integral structure.

6. The large-size 4-station vertical electric turret enables the machine tool to have high processing efficiency and more effectively ensure the precision of the inner hole thread of the fine turning.

Specification

| Model and specifications | QK1322 |

| Guideway width | 550 mm |

| Max. swing over bed | 630mm |

| Max. swing over carriage | 350mm |

| Hole through spindle | 200mm |

| Max. processing Pipe diameter | 196mm |

| Max. workpiece length | 1500/3000 mm |

| Range of spindle speed changes (r/min) | 24~300 |

| Tool post style | Vertical 4 Stations |

| Knife rest translocation time(S) | 3S |

| Repeated positioning accuracy | ±0.002 |

| Processing workpiece precision | IT7 |

| Bed quenching hardness | HRC52 |

| Workpiece surface roughness | Ra1.6 |

| Power of main motor | 7.5/11kw |

| NC system | Guangtai130IT/Guangshu980TA2 (According to customer's requirement ) |

| Chuck | 500 3-jaw |

FAQ:

FAQ: 1.Q: Which trade term I can choose?

A: You can choose FOB,FCA

2.Q: How can I get quotation from you?

A: You can make the inquiry online on made-in-china, or send email to us. It is better if you can tell what is your detailed request information. We will reply to you within 24 hours on work days, and within 48 hours on holiday.

3.Q: how can I make the payment?

A: You can pay by T/T . You can also pay to my company business bank account.

4.Q:What is your delivery time ?

A:The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

We want to know:

Please tell us your specific purchasing requirements, so that we can make specific quotations.