- Overview

- Product Description

- Product Parameters

- Our Advantages

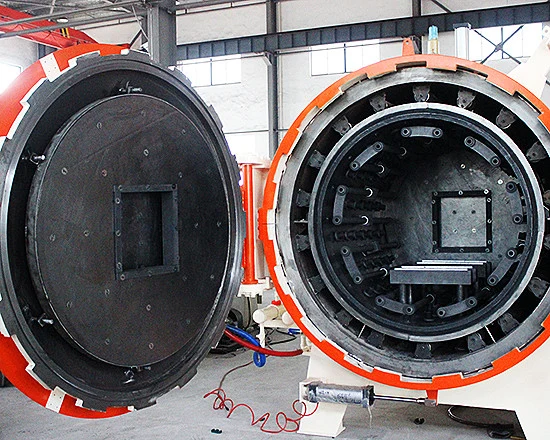

- WORKSHOP

- Packaging & Shipping

Basic Info.

Product Description

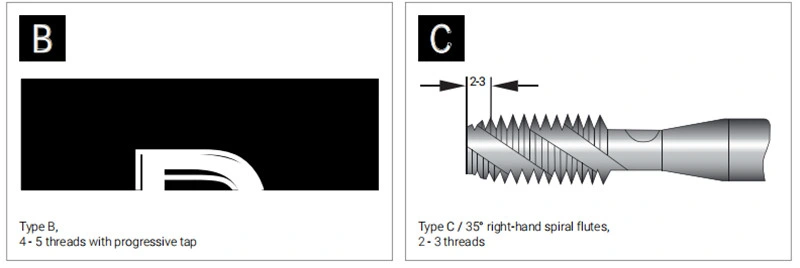

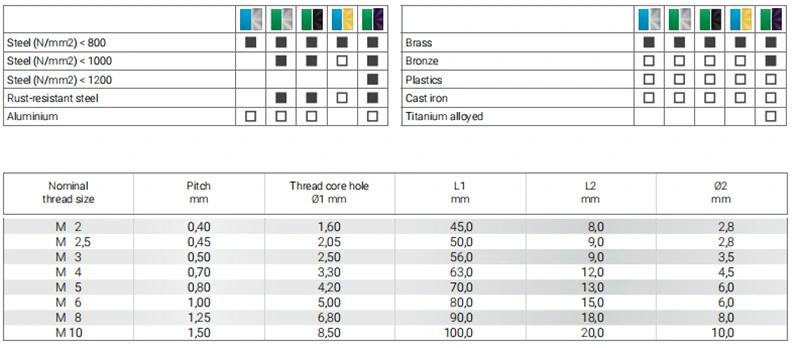

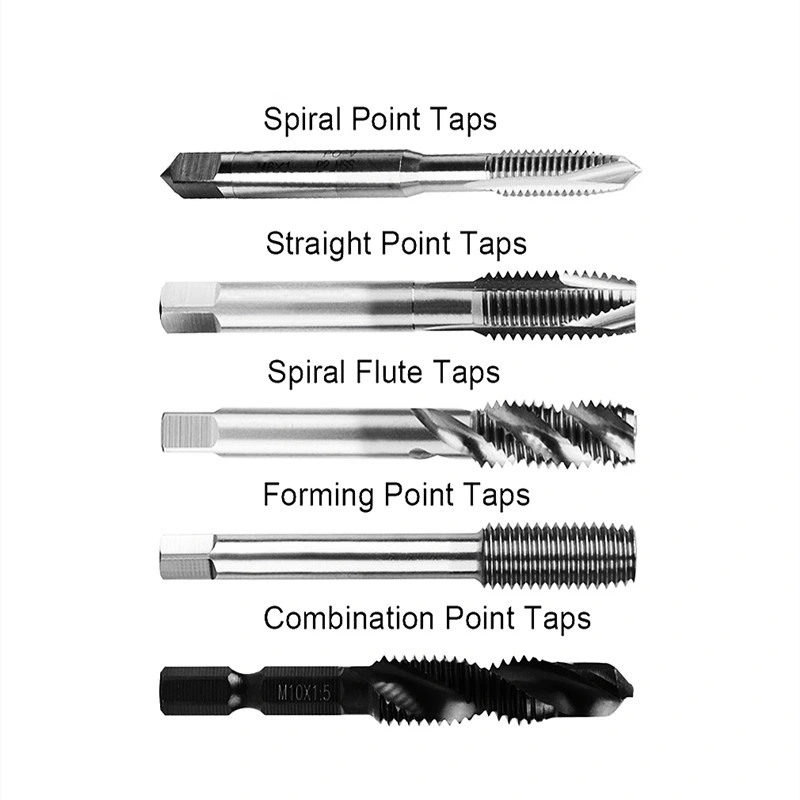

Machine tap with reinforced shank, for through threads in aluminium, aluminium alloys, bronze,copper, nickel and plastics.

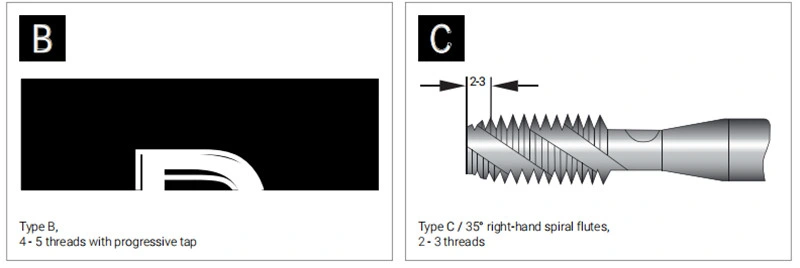

- To cut an internal thread, at first a core hole is drilled, whose diameter is approximately smaller by the pitch of the thread than the nominal diameter of the thread.

- Subsequently tapered counter bores are placed,which match the size of the thread diameterplus 10% of it. This is done to get a better insertion into the bore hole and to prevent the first and the last thread from being pushed out when beginning to cut.

- Then the taps are screwed in and out in order.The final core hole diameter is created through the additional plastic deformation of the thread flanks.

The Spiral Point machine tap consists of cobalt alloyed and vaporised heavy duty high-speed steel. For through threads and bottoming threads in unalloyed and alloyed steels up to a strength of 1000 N/mm², staniless steel, malleable cast iron and non-ferrous metals. The thread is cut inone operation.

1. Package:Plastic box,

2. Delivery:35 Days after your deposite

3. Shipping:By sea,By air,if small order,we can provide the Express.

Why choose us:

1. Experience : We are a supplier of many brands in Germany,usa,Russia,Brazil and so on . So we have the confidence to provide you with the best service.

2. Quality Control : Quality Control System from STARRY Germany ensure our STARRY Factory's products and service QUALITY which have strict processing quality Control for every step.

3. Service : We offer OEM&ODM service.and we accept trial order. If you find any problem. we'll find the suitable solution.

4. Product : We have confidence in the quality of our products.and the product prices are also competitive.