- Overview

- Product Description

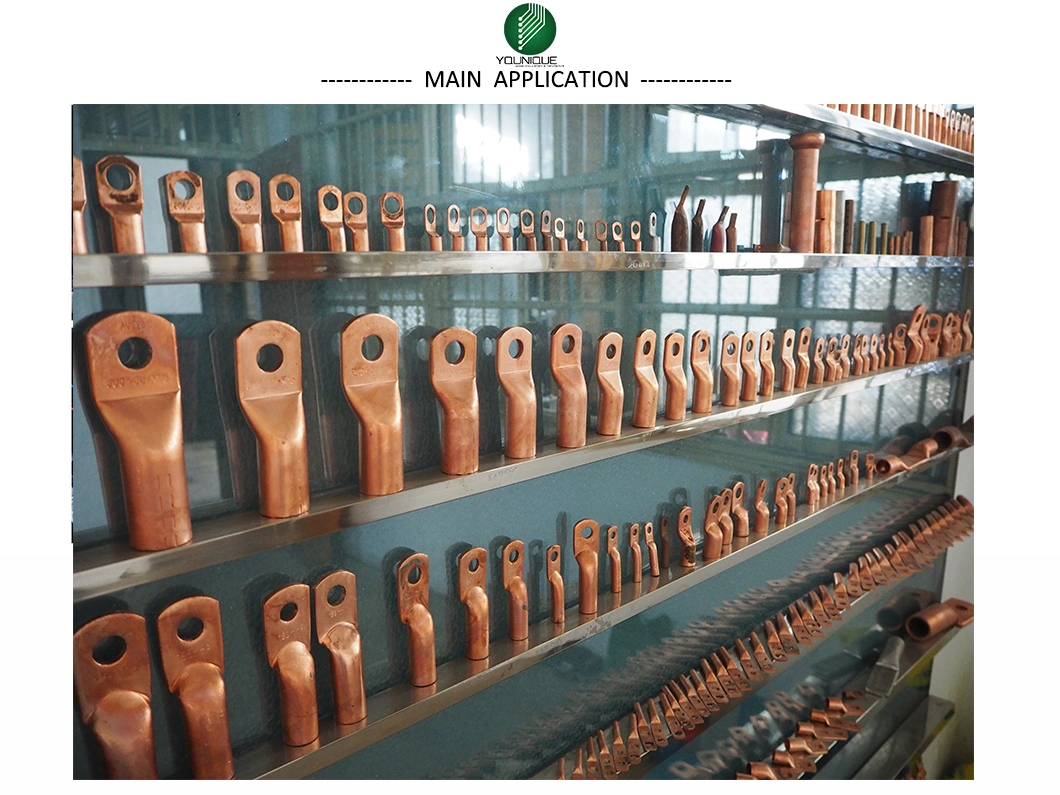

- Main Application

- Company Profile

- Certifications

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Overview

A stamping die is a special, one-of-a-kind precision tool. It can cut and form sheet metal into a desired shape or outline.

The cutting and forming part of a die is usually made of a special type of hardenable steel called tool steel.

Dies may also contain cutting and forming parts, which are made of carbide or a variety of other hard, wear-resistant materials.

Stamping is a cold-forming operation, which means that no heat is introduced into the die or the sheet material intentionally.

Terminal lug stamping die - It is a stamping die for cutting and forming the terminal ear. The terminal lugs include rings, spades, pins, blades, and female-male disconnects.

Technical Parameters

| Application | custom terminal lug stamping die |

| Die life | 200 Million |

| Blade life | > 2 Million |

| Stamping speed | 300 strokes/ min |

| Die structure | Two-plate, four guide pillar |

| Die base material | SKD11 |

| Plate material | Cr12 |

However, due to the heat generated by friction during cutting and forming, stamping parts often exit the die very hot.

- Progressive, single hit, short-run, compound dies, and more.

- Stamping operations include blanking, bending, forming, coining, lancing, extruding, etc.

- Tool Steel and Carbide Dies.

- All dies are specially tailored to your project.

We customize stamping die according to the customer's requirement.

Terminal lug stamping die is one of the types of stamping die we accept custom.

- Aluminum Stamping

- Automotive Stamping

- Fourslide Stamping

- Metal Stamping

- Progressive Die Stamping

- Long Run, High-Speed Stamping

- Stainless Steel Stamping