- Overview

- Product Description

- Detailed Photos

- Certifications

- Company Profile

- FAQ

Basic Info.

Product Description

JICHUN will manufacture and supply your custom Fibro guide pillar details for use with high velocity jet cooling technology to treat soldering and shrink porosity.For best results, core pins with small diamter cooling channels should be manufactured from premium round stock and heat treated to 48-52HRC prior to finishing.Best practice in design is to manufacture a cooling channel to within 10mm of the core pin tip. It is also adviseable to plan for the largest possible diameter cooling channel and thinnest wall section in order to move heat away from critical areas.

JICHUN will manufacture and supply your custom Fibro guide pillar details for use with high velocity jet cooling technology to treat soldering and shrink porosity.For best results, core pins with small diamter cooling channels should be manufactured from premium round stock and heat treated to 48-52HRC prior to finishing.Best practice in design is to manufacture a cooling channel to within 10mm of the core pin tip. It is also adviseable to plan for the largest possible diameter cooling channel and thinnest wall section in order to move heat away from critical areas.

Basic Information:

| Manufacture | Jichun Mould Standard Parts Co., Ltd. |

| Services available | Press Die Components,Plastic Mold Components, Automation Components,etc. |

| Industry | Automotive, Medical, Cosmetics, Mobile Phone, Equipment manufacturing, |

| Mould parts size | According to customer requirements |

| Material | SKD61, SKD11, SKH-51, SUJ2, S45C, 1.2343, 1.2344, 1.2767, etc |

| Standard | DIN, AISI, JIS, MISUMI,SNAKYO,HASCO,MEUSBURGER,DME, etc. |

| Tolerance | As per standard or drawing |

| Surface | Nitriding, Titanium coating, Blacking, DLC coating, etc. |

| Delivery | 5-25 days after payment according to order quantity |

| Package | in bubble bag, plastic bag, carton, wooden case, or Customized |

| QC System | 100% inspection before shipment |

| Inspection Equipment | HEXAGON, ZEISS |

| Equipment | Wire Cutting Machine: Switzerland Agie Charmilles, etc. |

| EDM: China OUWEN, Taiwan Miki, etc. | |

| Plain Grinding Machine: Taiwan DAWN, Japan OKAMOTO, etc. | |

| Circular Grinding Machine: China, Taiwan Tengchang etc. | |

| Vertical Milling: China Today CNC, etc. | |

| Lather Machine: Taiwan, China Today CNC, German DMG, etc. | |

| CNC Machine: China, Taiwan, Japan Mori Seiki, German DMG MORI |

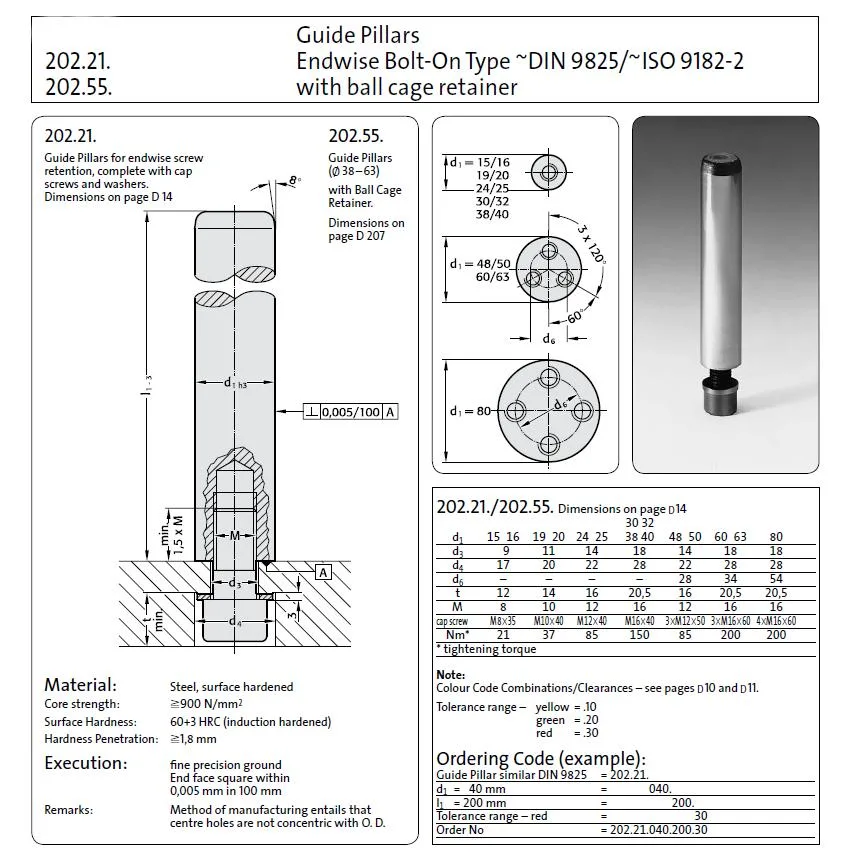

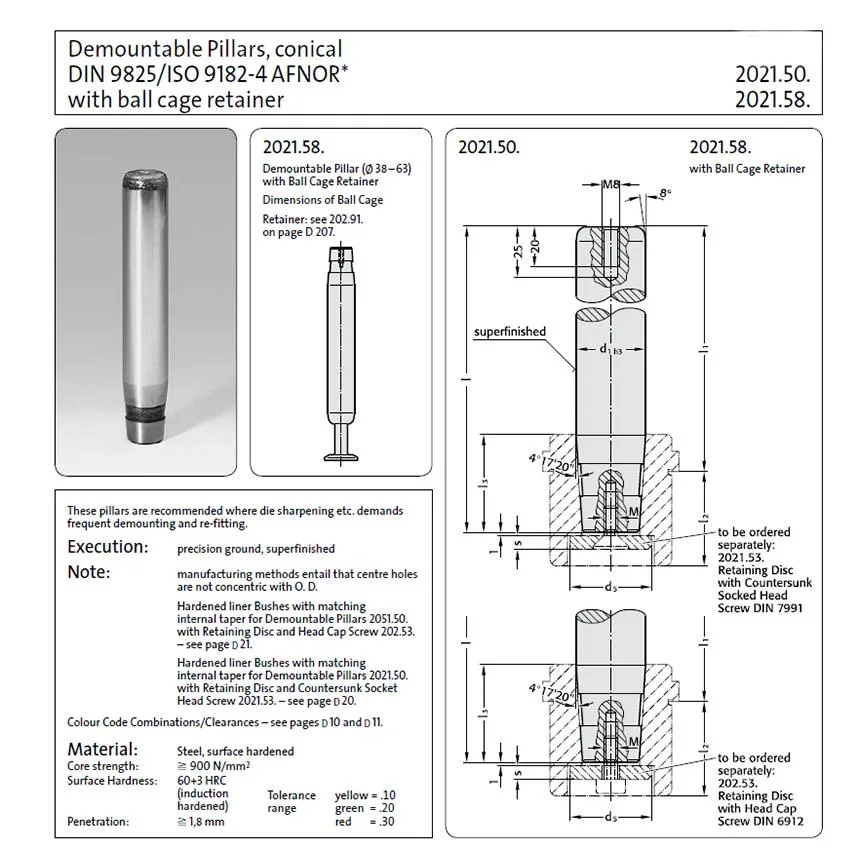

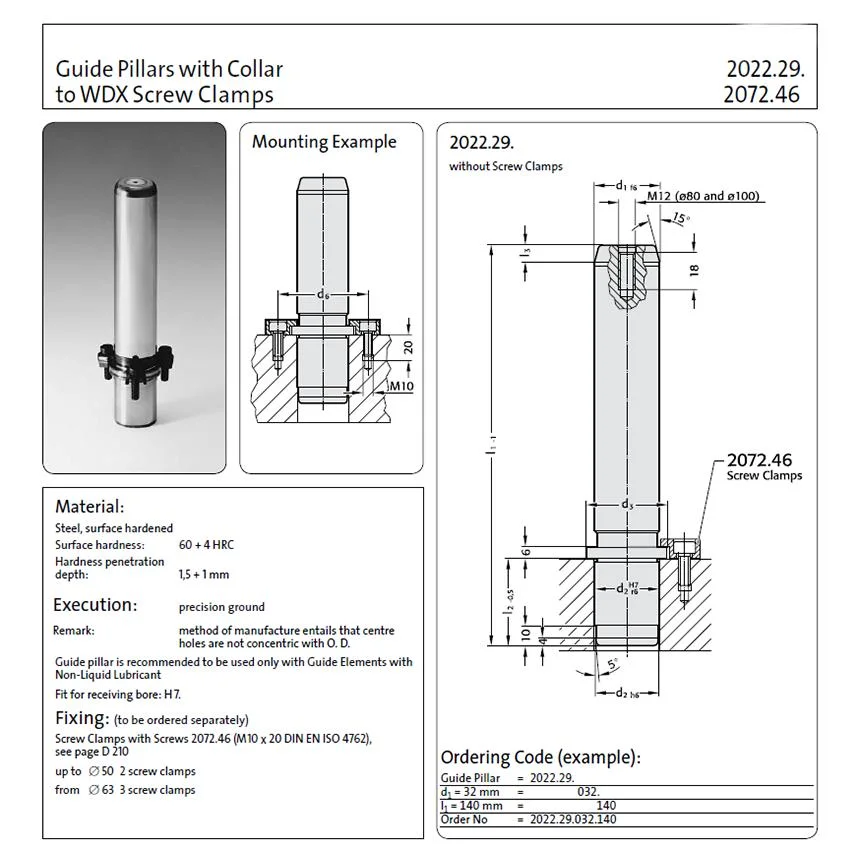

Fibro Standard

Strictly control the product quality and ensure that the products are 100% qualified.

Dongguan Jichun Mould Standard Parts Co., Ltd. was founded in 1997. 3 factories, 5 warehouses, 95 precision processing equipment, millions of product inventory. The factory is located in Dongguan, Guangdong Province, China. At present, it specializes in producing various stamping die parts, plastic die parts, automotive die parts, FA automation parts, various kinds of mechanical parts. [Main Products] Guide Pins,Guide bush,Stripper Guide Pin,Stripper Guide bush,Holder Guide Post Sets,Ball Guide Post Sets For Die Sets,Plain Guide Post Sets For Die Sets,Guide Posts For Die Sets,Oil-Free Slide Plates,Punches & Dies,Punches,Punch Guide Bushings,Retainers,Coil Springs,Gas Springs

[Main Products] Guide Pins,Guide bush,Stripper Guide Pin,Stripper Guide bush,Holder Guide Post Sets,Ball Guide Post Sets For Die Sets,Plain Guide Post Sets For Die Sets,Guide Posts For Die Sets,Oil-Free Slide Plates,Punches & Dies,Punches,Punch Guide Bushings,Retainers,Coil Springs,Gas Springs

At the same time, we can manufacture according to the following criteria: Hasco / Misumi / DME / Pedrotti / Voest / Strack / Fibro / DIN / DAYTON / PUNCH / DANLY / Lmina.

How to get a quote? Send us the model or drawing you want.

How long is the delivery time? Standard parts in stock and 7-12 working days.

How can you ensure the quality? We have QC department to control the quality from the begining of production until goods finish.

What is your terms of payment? Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Danny Yang