Basic Info.

Model NO.

KY1204

Pieces

10PCS

Application

Motorize, Manual

Customized

Customized

Transport Package

Plastic Box in Export Carton

Specification

M1.0*0.25

Trademark

KAYA

Origin

Shenzhen

HS Code

8207400000

Production Capacity

20000PCS/Month

Product Description

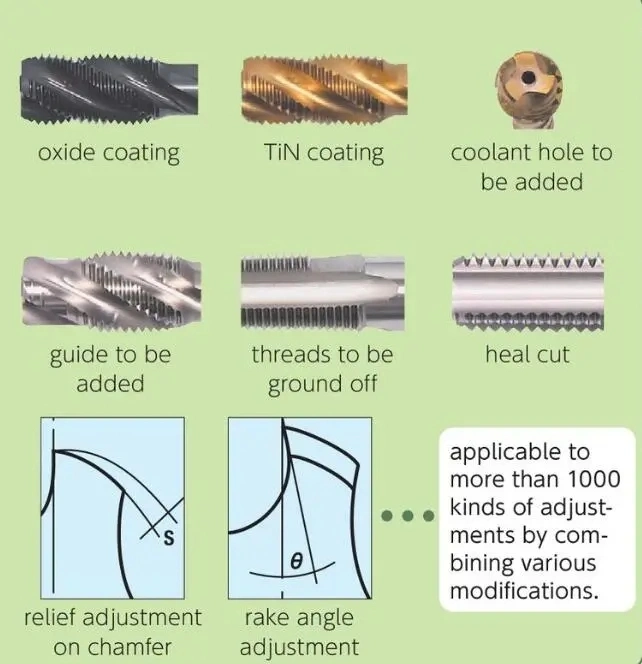

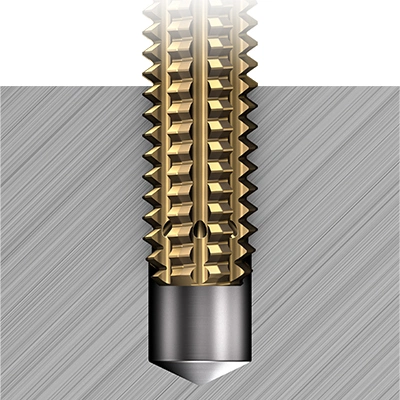

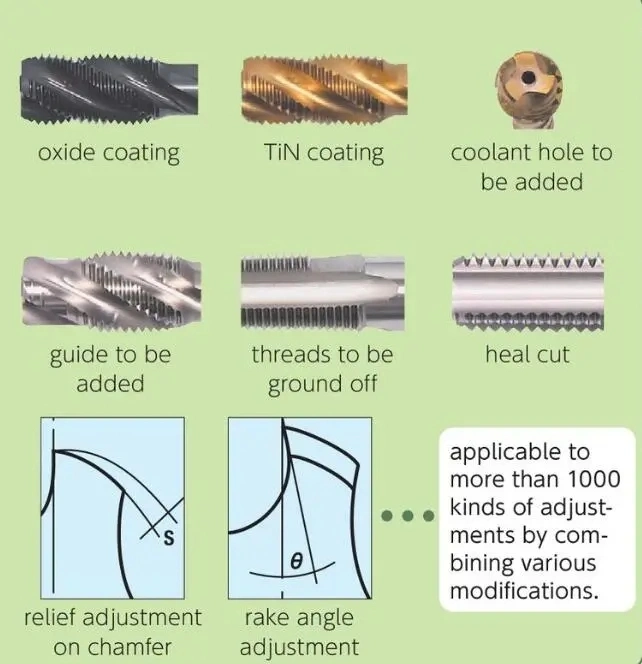

Y010001 Cobalt HSS Forming Taps is a high-speed, chip-free forming tap suitable for both through- and blind-holes in steel, stainless steel, aluminium and HRSAs. Versatile and optimized forming taps are available, with and without oil grooves, in an assortment of diameters, grades, coatings and thread forms to suit a range of applications.

Product Sizes:

Customized Items are Available.

The tapping range consits of Versatile, Optimized and Customized solutions within the Solid Round Tools product offer.

- Versatile solutions features a complete range of high performance tools that offer high flexibility and cost efficiency.

- Optimized solutions feature a unique line of refined tools for specific needs that provide extreme efficiency, reliability and durability.

- Customized solutions feature Tailor Made and Advanced Engineered products, individually designed to meet the highest demands on performance.

| Procuct Name | HSS Titanium Forming Tap for Steel Aluminium Stainless Steel Tapping |

| Flute Type | Straight Flute (Spiral Flute, Spiral Point are Available) |

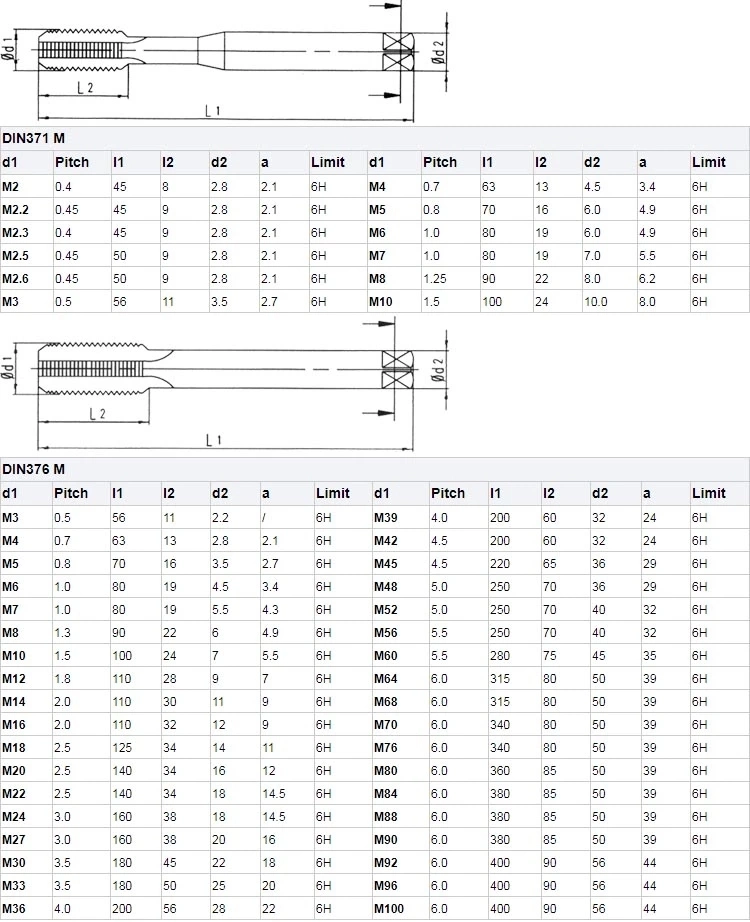

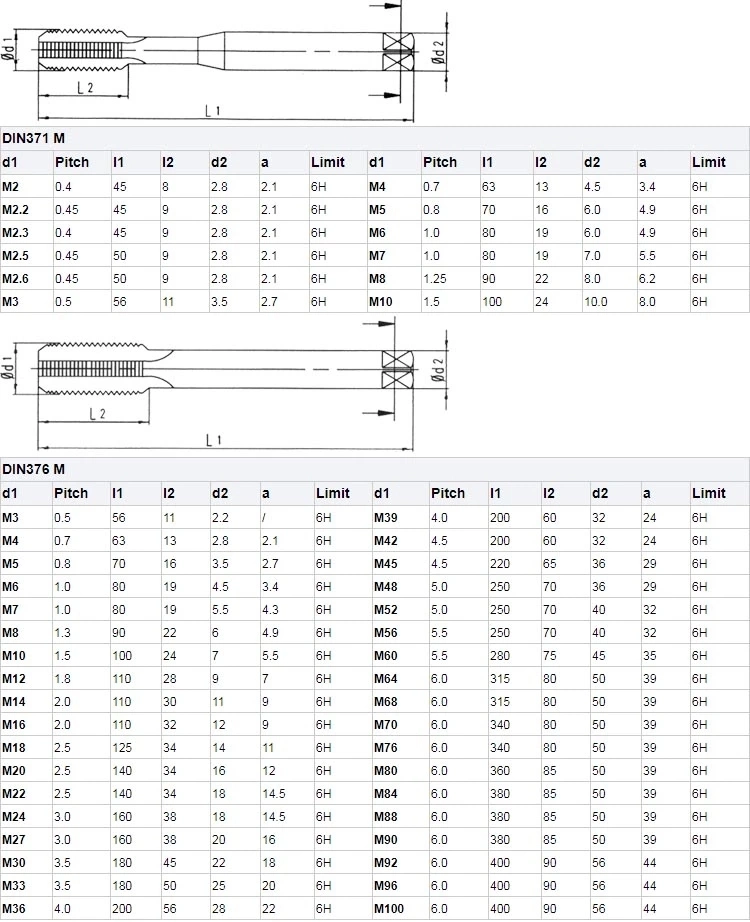

| Standard | Metric, JIS, DIN371 / DIN376 (ANSI Standard is Available) |

| Size | M1-M30 |

| Thread Type | M (MF, UNC, UNF, BSW, BSP are Available) |

| Material | HSS (Alloy Steel is Available) |

| Process | Fully Ground |

| Shank Type | According to customer requirement |

| Surface Finish | Blank (Tin-Coated, other High Performance Coating are Available) |

| Package | 10pcs in One PVC Pouch or in Plastic Box |

| Features | 1.Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation 4.Suitable for variety of materials due to its chipless machining process. 5.Large center diameter of the tap leads to higher endurance and torsional strength, longer tool life, and not easily broken. |

Product Sizes:

Customized Items are Available.