Basic Info.

Packaging & Delivery

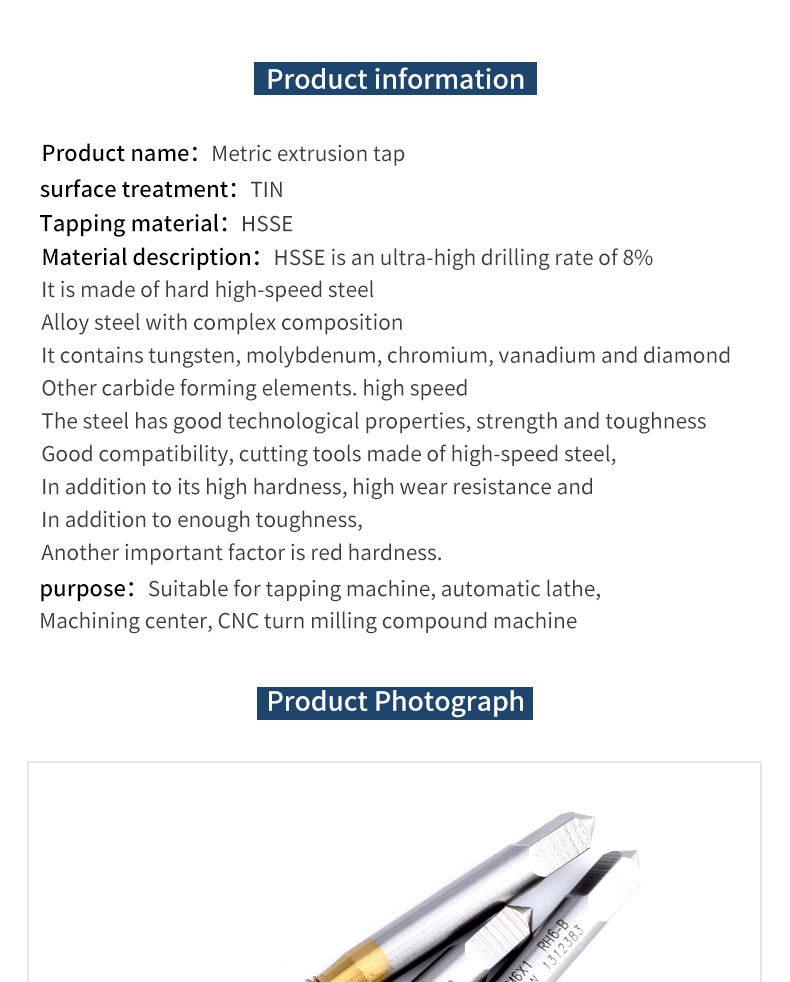

Product Description

Applicable Workpiece:

suitable for low carbon steel, medium carbon steel, high carbon steel, alloy steel, stainless steel, copper and alloy castings, etc., which does not produce crushed chips; the processing effect of steel is better.

Note:

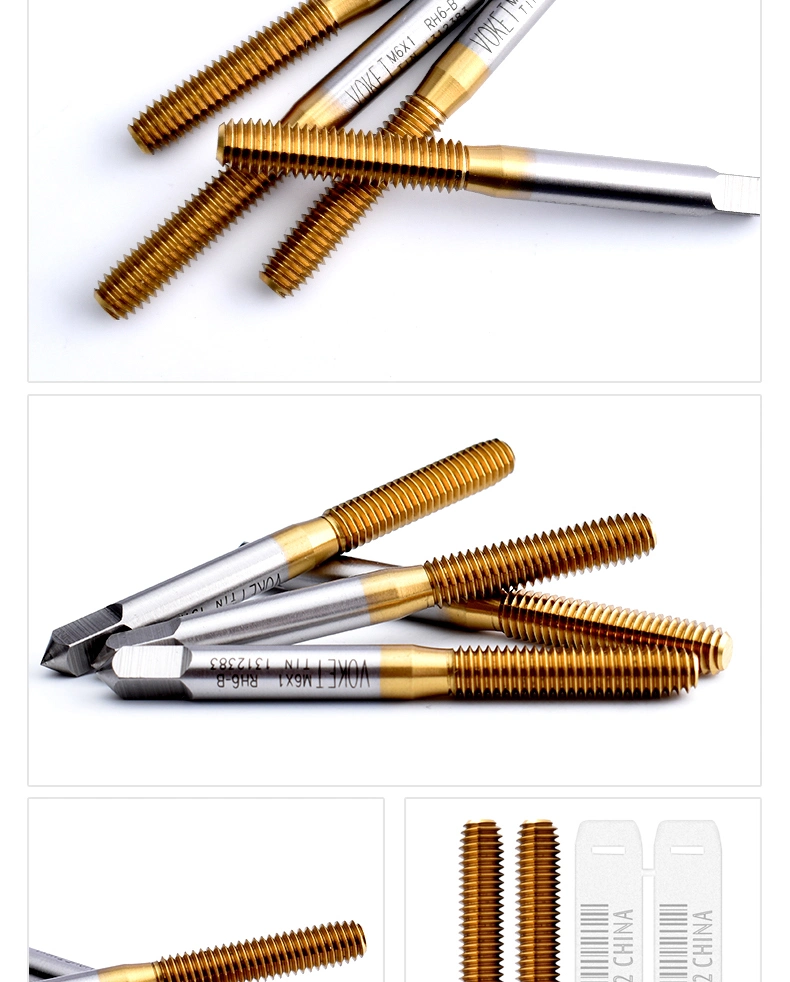

Forming Tap / Roll Tap wire tapping is a plastic forming method in which the grinding material is embossed in the lower hole to form a thread. Therefore, no chipping occurs, and there is no chip flute, so it is also called a ditchless (chip) wire tap. This tapping does not damage the thread or the tapping due to problems such as chipping. Extrusion tapping is best suited for plastic materials such as aluminum, copper, zinc, brass and mild steel. When using the extrusion tapping, the size of the lower hole must be selected according to the precision requirements, so that the high-precision, high-quality thread can be molded. For the material characteristics and coating conditions, we have a variety of different precision grades. For customers to use.

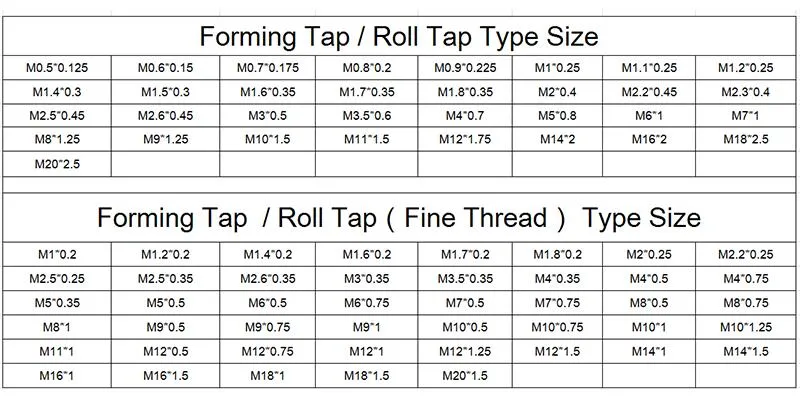

| Product Name | Forming Tap / Roll Tap |

| Material | HSSE-42 |

| Standard | JIS |

| Surface Finishing | Tin Coating |

| HRC | 20/30/45/55/60/65 Degree |

| Usage | Forming Tap / Roll Tap is a plastic forming method in which the grinding material is embossed in the lower hole to form a thread. Therefore, no chipping occurs, and there is no chip flute, so it is also called a ditchless (chip) wire tap. This tapping does not damage the thread or the tapping due to problems such as chipping. |

| Processing material | low carbon steel, medium carbon steel, high carbon steel, alloy steel, stainless steel, copper and alloy castings, etc., which does not produce crushed chips; the processing effect of steel is better. |

| Application | Automotive, aviation, aerospace enterprise, motorcycle engine, diesel engine, carburetor, compressor, mold industry, ect |