- Overview

- Product Description

- Product Parameters

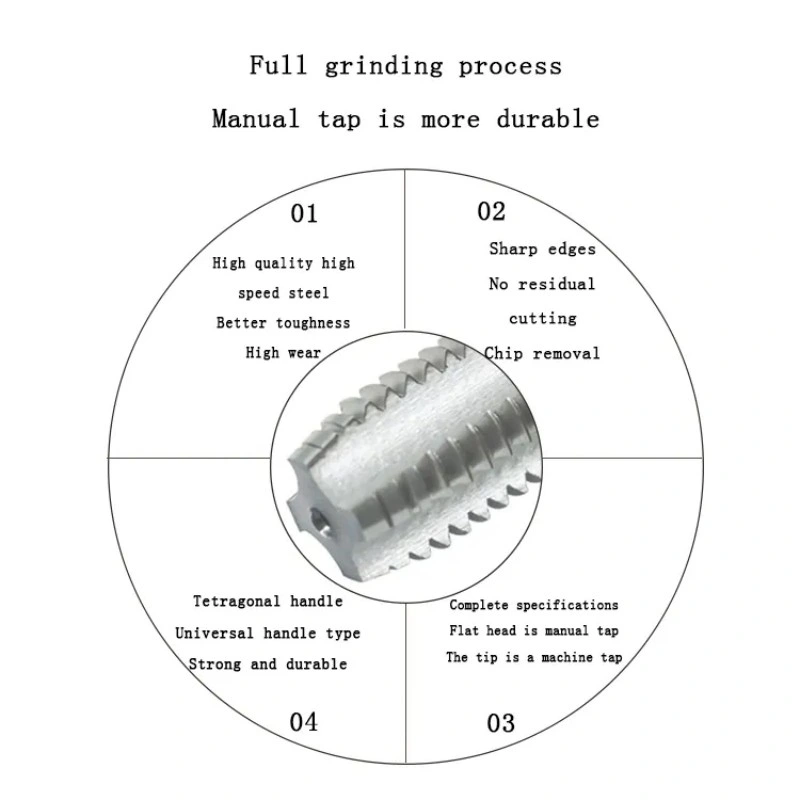

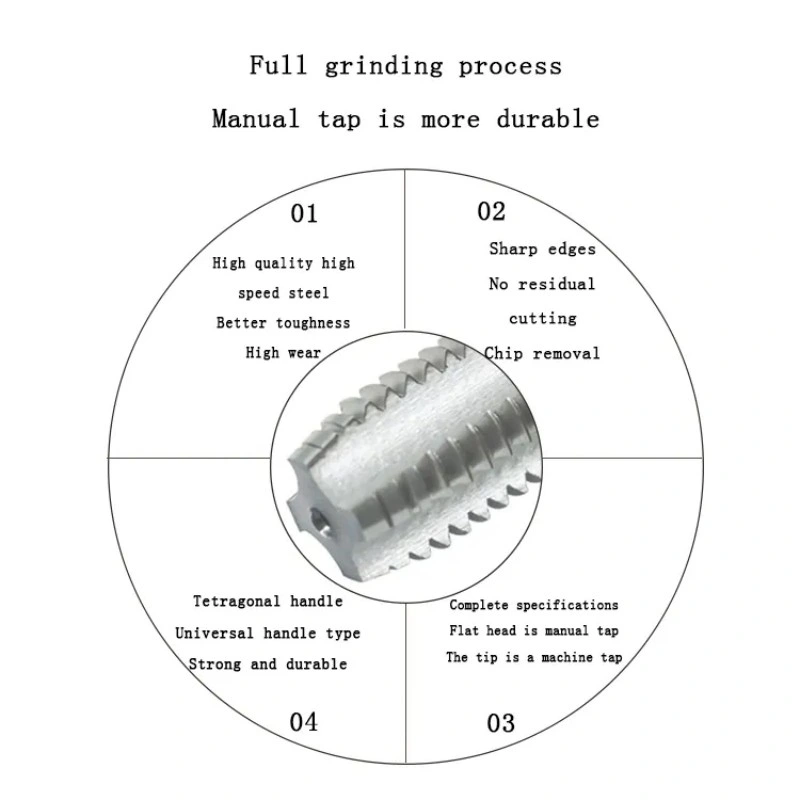

- Our Advantages

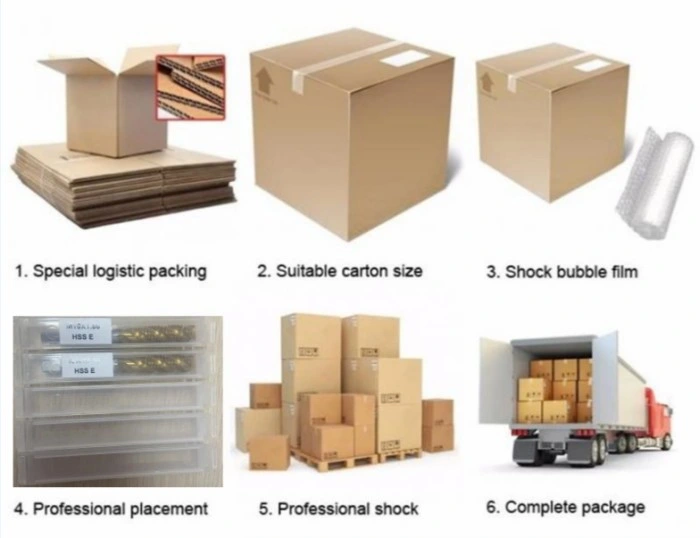

- Packaging & Shipping

- WORKSHOP

- Certifications

- FAQ

Basic Info.

Model NO.

M6X1.0

Pieces

3PCS

Application

Motorize, Manual

Customized

Non-Customized

Tolerance

6h

Surface Finishing

Tin Coated

Type

Tap

Sample

Available

Transport Package

Plastic Box

Specification

M6x1.0

Trademark

STARRY

Origin

Yangzhou

HS Code

82074000

Production Capacity

300000PCS Per Mouth

Product Description

Size: M6x1.0 Forming Thread Taps.

Cutting Direction: Right Hand.

Material: M35(HSS 5% Co).

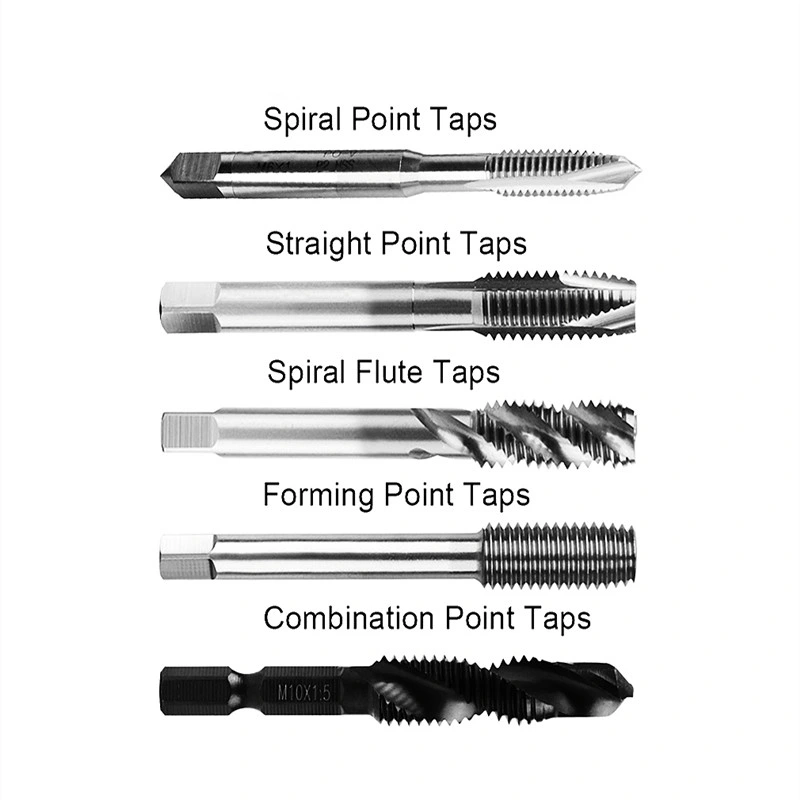

Forming Thread Taps

Forming taps extrusion of internal threads is a chip-less process, especially suitable for lower strength and better plasticity of copper and aluminum alloys, but also for stainless steel and low carbon steel and other materials with low hardness and high plasticity tapping.

Easy to Use:

It can be used with manual equipment or special processing consoles, such as tapping machines, drill-in-one bench drills, CNC lathes, machining centers, etc.

1. Before tapping confirm whether the diameter of the round hole is appropriate, and to take protective measures when working.

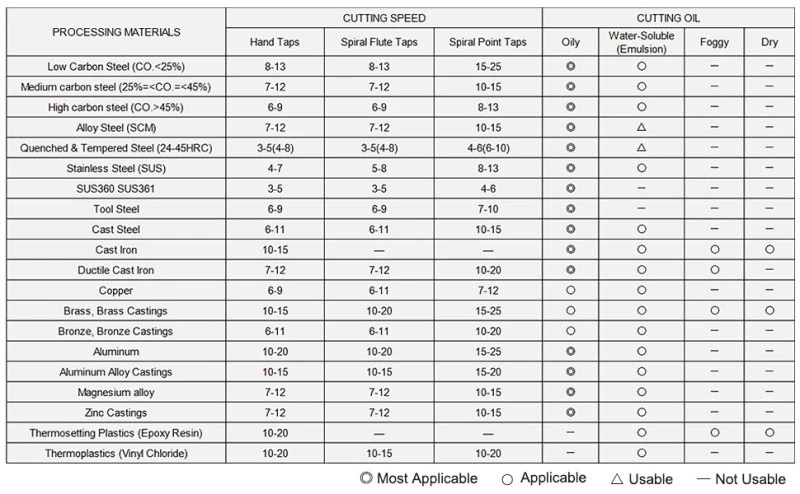

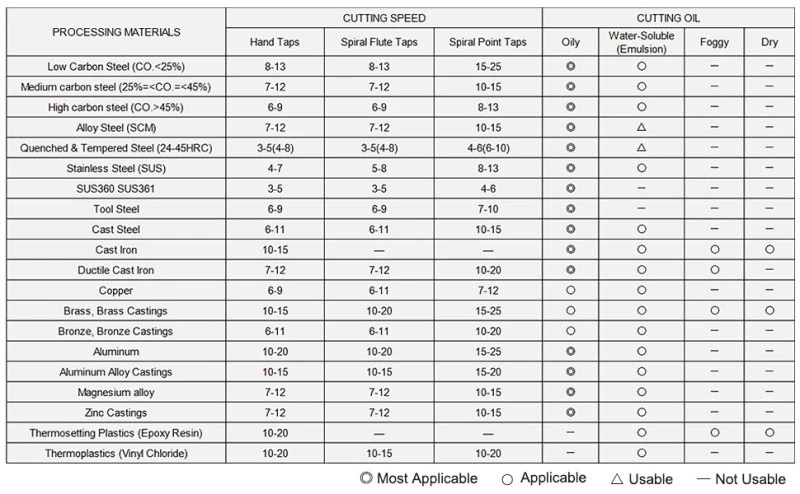

2. When tapping, it is necessary to add water or coolant to cool down to prevent excessive temperature and reduce tap loss. If it encounters difficulty in rotation, the tapping should be suspended.

3. Be sure to select the appropriate cutting oil for the complex tapping process and apply anti-rust oil for maintenance after use.

Cutting Direction: Right Hand.

Material: M35(HSS 5% Co).

Forming Thread Taps

Forming taps extrusion of internal threads is a chip-less process, especially suitable for lower strength and better plasticity of copper and aluminum alloys, but also for stainless steel and low carbon steel and other materials with low hardness and high plasticity tapping.

Easy to Use:

It can be used with manual equipment or special processing consoles, such as tapping machines, drill-in-one bench drills, CNC lathes, machining centers, etc.

1. Before tapping confirm whether the diameter of the round hole is appropriate, and to take protective measures when working.

2. When tapping, it is necessary to add water or coolant to cool down to prevent excessive temperature and reduce tap loss. If it encounters difficulty in rotation, the tapping should be suspended.

3. Be sure to select the appropriate cutting oil for the complex tapping process and apply anti-rust oil for maintenance after use.

| Product name | JIS HSS-M35 forming tap |

| Flute Type | forming kinds |

| Standard | JIS |

| Process | Fully ground |

| Size | M1-M50 |

| Surface | Bright Finish (Tin-coated, other High Performance Coating are Available) |

| Shank Type | Square Shank |

| Package | 1Pieces in One Plastic Box |

| Thread Type | M/MF, UNC/UNF are Available |

| Features | 1.Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled sae tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation 4.The straight flute is the standard style of tap, designed for a range of different tapping applications. 5.A straight flute tap can be used in through or blind holes. |

| Size | Overall Len | Thread Len | |||

| M1x0.2 | 30 | 6 | |||

| M1x0.25 | 30 | 8 | |||

| M1.1x0.2 | 32 | 6 | |||

| M1.1x0.25 | 32 | 9 | |||

| M1.2x0.2 | 32 | 6 | |||

| M1.2x0.25 | 32 | 9 | |||

| M1.4x0.2 | 34 | 6 | |||

| M1.4x0.3 | 34 | 11 | |||

| M1.6x0.2 | 36 | 6 | |||

| M1.6x0.35 | 36 | 13 | |||

| M1.7x0.2 | 36 | 6 | |||

| M1.7x0.35 | 36 | 13 | |||

| M1.8x0.2 | 36 | 6 | |||

| M1.8x0.35 | 36 | 13 | |||

| M2x0.25 | 40 | 8 | |||

| M2x0.4 | 40 | 15 | |||

| M2.2x0.25 | 42 | 8 | |||

| M2.2x0.45 | 42 | 15 | |||

| M2.3x0.4 | 42 | 15 | |||

| M2.5x0.35 | 44 | 10 | |||

| M2.5x0.45 | 44 | 16 | |||

| M2.6x0.45 | 44 | 16 | |||

| M3x0.35 | 46 | 10 | |||

| M3x0.5 | 46 | 18 | |||

| M3.5x0.35 | 48 | 10 | |||

| M3.5x0.6 | 48 | 18 | |||

| M4x0.5 | 52 | 15 | |||

| M4x0.7 | 52 | 20 | |||

| M4x0.75 | 52 | 20 | |||

| M4.5x0.5 | 52 | 15 | |||

| M4.5x0.75 | 55 | 20 | |||

| M5x0.5 | 52 | 15 | |||

| M5x0.8 | 60 | 22 | |||

| M5.5x0.5 | 52 | 15 | |||

| M6x0.75 | 62 | 20 | |||

| M6x1 | 62 | 24 | |||

| M7x0.75 | 62 | 20 | |||

| M7x1 | 65 | 26 | |||

| M8x0.75 | 62 | 20 | |||

| M8x1 | 70 | 30 | |||

| M8x1.25 | 70 | 30 | |||

| M9x0.75 | 62 | 20 | |||

| M9x1 | 70 | 30 | |||

| M9x1.25 | 72 | 30 | |||

| M10x0.75 | 62 | 20 | |||

| M10x1 | 70 | 30 | |||

| M10x1.25 | 75 | 32 | |||

| M10x1.5 | 75 | 32 | |||

| M11x0.75 | 62 | 20 | |||

| M11x1 | 70 | 30 | |||

| M11x1.5 | 80 | 38 | |||

| M12x1 | 70 | 30 | |||

| M12x1.25 | 80 | 38 | |||

| M12x1.5 | 82 | 38 | |||

| M12x1.75 | 82 | 38 | |||

| M14x1 | 70 | 30 | |||

| M14x1.25 | 88 | 42 | |||

| M14x1.5 | 88 | 42 | |||

| M14x2 | 88 | 42 | |||

| M15x1 | 70 | 30 | |||

| M15x1.5 | 90 | 42 | |||

| M16x1 | 75 | 30 | |||

| M16x1.5 | 95 | 45 | |||

| M16x2 | 95 | 45 | |||

| M17x1 | 80 | 30 | |||

| M17x1.5 | 95 | 45 | |||

| M18x1 | 80 | 30 | |||

| M18x1.25 | 95 | 45 | |||

| M18x1.5 | 95 | 45 | |||

| M18x2 | 95 | 45 | |||

| M18x2.5 | 100 | 48 | |||

| M20x1 | 80 | 30 | |||

| M20x1.5 | 95 | 45 | |||

| M20x2 | 95 | 45 | |||

| M20x2.5 | 105 | 50 | |||

| M22x1 | 85 | 30 | |||

| M22x1.5 | 95 | 45 | |||

| M22x2 | 95 | 45 | |||

| M22x2.5 | 115 | 55 | |||

| M24x1 | 90 | 30 | |||

| M24x1.5 | 95 | 45 | |||

| M24x2 | 95 | 45 | |||

| M24x3 | 120 | 58 | |||

| M25x1 | 95 | 30 | |||

| M25x1.5 | 95 | 45 | |||

| M25x2 | 95 | 45 | |||

| M26x1.5 | 95 | 45 | |||

| M26x3.5 | 130 | 62 | |||

| M27X1 | 95 | 30 | |||

| M27x1.5 | 95 | 45 | |||

| M27x2 | 95 | 45 | |||

| M27x3 | 130 | 62 | |||

| M28x1 | 105 | 30 | |||

| M28x1.5 | 105 | 45 | |||

| M28x2 | 105 | 45 | |||

| M30x1 | 105 | 30 | |||

| M30x1.5 | 105 | 45 | |||

| M30x2 | 105 | 45 | |||

| M30x3 | 135 | 65 | |||

| M30x3.5 | 135 | 65 | |||

| M32x1.5 | 105 | 45 | |||

| M32x2 | 105 | 45 | |||

| M32x3.5 | 145 | 70 | |||

| M33x1.5 | 110 | 45 | |||

| M33x2 | 110 | 45 | |||

| M33x3 | 145 | 70 | |||

| M33x3.5 | 145 | 70 | |||

| M34x3.5 | 145 | 70 | |||

| M35x1.5 | 110 | 45 | |||

| M36x1.5 | 110 | 45 | |||

| M36x2 | 110 | 45 | |||

| M36x3 | 155 | 75 | |||

| M36x4 | 155 | 75 | |||

| M38x1.5 | 115 | 45 | |||

| M39x1.5 | 115 | 45 | |||

| M39x2 | 115 | 45 | |||

| M39x3 | 165 | 80 | |||

| M39x4 | 165 | 80 | |||

| M40x1.5 | 115 | 45 | |||

| M40x2 | 115 | 45 | |||

| M40x3 | 165 | 80 | |||

| M42x1.5 | 120 | 45 | |||

| M42x2 | 120 | 45 | |||

| M42X3 | 175 | 80 | |||

| M42x4 | 175 | 80 | |||

| M42x4.5 | 175 | 85 | |||

| M45x1.5 | 120 | 45 | |||

| M45x2 | 120 | 45 | |||

| M45x3 | 180 | 80 | |||

| M45x4 | 180 | 80 | |||

| M45x4.5 | 180 | 85 | |||

| M48x1.5 | 125 | 45 | |||

| M48x2 | 125 | 45 | |||

| M48x3 | 180 | 80 | |||

| M48x4 | 180 | 80 | |||

| M48x5 | 185 | 90 | |||

| M50x1.5 | 130 | 45 | |||

| M50x2 | 130 | 45 | |||

| M50x3 | 180 | 80 | |||

1. Package:Plastic box,

2. Delivery:35 Days after your deposite

3. Shipping:By sea,By air,if small order,we can provide the Express.

Q:What is your MOQ?

A:It depends on specific products.please contact us for more information

Q:What if the products arrived damaged?

A:Send us the photo of damaged products to confirm,we will replace them in your next order

Q:What is your delivery terms?

A:We accept EXW,FOB,etc. We will choose the most convenient one foe you with less cost

Q:How many markets do you have?

A:Germany Dubai Russia etc

Q:Can I buy a sample for testing?

A:yes we accept the sample orders

Q:How can I contact with you?

A:You can send us inquiry directly through alibaba.or you can contact through any method listed below

A:You can send us inquiry directly through alibaba.or you can contact through any method listed below