Basic Info.

Model NO.

ALL size

Brand

Waheynao

Standard

DIN

Application for Machine Tool

Machine Taps

Pieces

20

Application

Motorize, Manual

Customized

Non-Customized

Usage

Internal Screw Thread Making

Hardness

45-65 HRC

Materials

HSS-M2.HSS-M35,HSS-Pm

Types

JIS,ISO,DIN

Coating

Tin,Ticn,Tiain

Delivery Time

7-30days

Shipping

by Air,EMS,DDP.etc

Flute Types

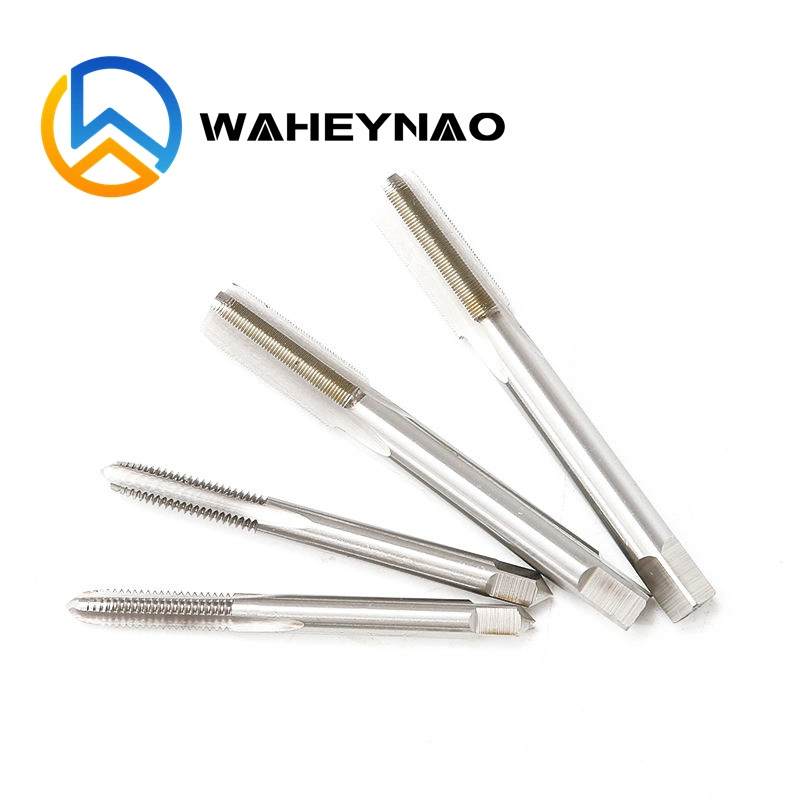

Spiral Flute,Straight Flute,Spiral Point

Transport Package

Stanard Box

Specification

M2. M3, M4, M5, M6, M7, M8, M9

Trademark

WAHEYNAO

Origin

China

HS Code

8207400000

Production Capacity

6 Million PCS Annually

Packaging & Delivery

Package Size

20.00cm * 10.00cm * 6.00cm

Package Gross Weight

0.100kg

Product Description

Features and benefits

• Ideal for hand tapping with a tap wrench or power tool depending on the application

• Available in a variety of thread sizes

• Manufactured using durable HSS

• Blue stream tempered finish helping to reduce friction and produce a fine thread finish

• Available in a variety of types including taper, second and plug

• Available in a variety of thread sizes

• Manufactured using durable HSS

• Blue stream tempered finish helping to reduce friction and produce a fine thread finish

• Available in a variety of types including taper, second and plug

HSS taps/tungsten carbide tap

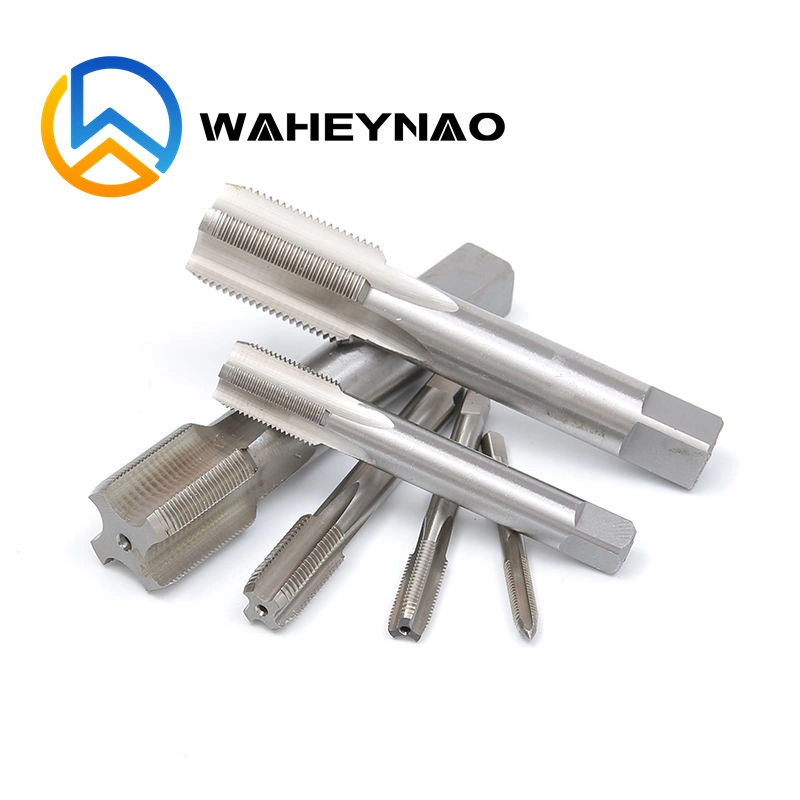

HSS Straight Flute Taps are used to cut threads in blind or through holes in most materials. They are manufactured to ISO529

standard and are suitable for hand or machine cutting.This versatile set contains three taps:

- Taper Cut (First tap) - Used for through holes or as a starter tap.

- Second Tap (Plug) - To follow the taper when tapping blind holes.

- Bottom Tap (Bottom) - For threading to the bottom of a blind hole.

standard and are suitable for hand or machine cutting.This versatile set contains three taps:

- Taper Cut (First tap) - Used for through holes or as a starter tap.

- Second Tap (Plug) - To follow the taper when tapping blind holes.

- Bottom Tap (Bottom) - For threading to the bottom of a blind hole.

High Performance Taps vs. HSS Standard Taps. Which is Right for Your Job?

If it is true that a workman is only as good as his tools, high-speed steel threading taps have created some of the greatest craftspeople the world has ever seen. Tough, hard, and wear resistant, these industry workhorses helped transform manufacturing, construction, automotive, aerospace, and many other industries in the wake of the Industrial Revolution. They continue to nobly serve industry, providing quality, fast, efficient threads day in and day out. But as industry continues to find new uses for hard and exotic materials, the need for even better tool materials has kept pace. There are increasingly broad areas where high-speed

steel taps cannot compete with the technologically-advanced chemistry,

FAQ

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in

your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price comfirmed, you can place an small trial order to test, but if you need only 1-2 pcs, we can send the free to you, and

you need to pay the shipping cost, please noted.

3) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 25-30 days.

4) What about the transportation and delivery date?

Normally, we use the DHL, TNT, UPS, FeDEx to send the goods, the shipping time around 5-7 days can be reach in your local

steel taps cannot compete with the technologically-advanced chemistry,

| Flute Type | Spiral Point (Straight Flute, Spiral Flute are Available |

| Standard | DIN352 (ANSI Standard is Available) |

| Size | M1-M100 |

| Thread Type | M (MF, UNC, UNF, BSW, BSP are Available) |

| Material | HSS (Alloy Steel is Available) |

| Process | Fully Ground |

| Shank Type | Square Shank |

| Surface Finish | Tin-Coated (Bright Finish, other High Performance Coating are Available) |

| Package | 10/5 Piece in One PVC Pouch or in Plastic Box |

| Features | 1.Ideal for rethreading fasteners and fastener holes for auto and machinery repair. 2.Precision milled sae tap and die set for cutting raw material or repair existing threads, remove screws and more function. 3.It can improve the efficiency of processing thread, a necessary tool for hand tapping operation 4.Spiral tap has a shallower flute passage than conventional taps. This gives the spiral point tap more cross-sectional area, which provides great strength, allows higher tapping speeds, and requires less power to drive. 5.Spiral point tap has the cutting face of the first few threads cut at a predetermined angle relative to the tap's axis angle to force the evacuation of chips ahead of the cutting action. |

FAQ

FAQ 1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in

your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price comfirmed, you can place an small trial order to test, but if you need only 1-2 pcs, we can send the free to you, and

you need to pay the shipping cost, please noted.

3) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 25-30 days.

4) What about the transportation and delivery date?

Normally, we use the DHL, TNT, UPS, FeDEx to send the goods, the shipping time around 5-7 days can be reach in your local