- Overview

- FAQ

Basic Info.

Model NO.

Customized

Technics

Bending Die

Process Combination

Single-Process Mould

Manufacturing Technology

Computer Technology

Driving Motor Type

Permanent Magnet

Mold Cavity Technology

EDM Milling

Milling Speed

High Speed

Parts Detection Method

Geometric Detection

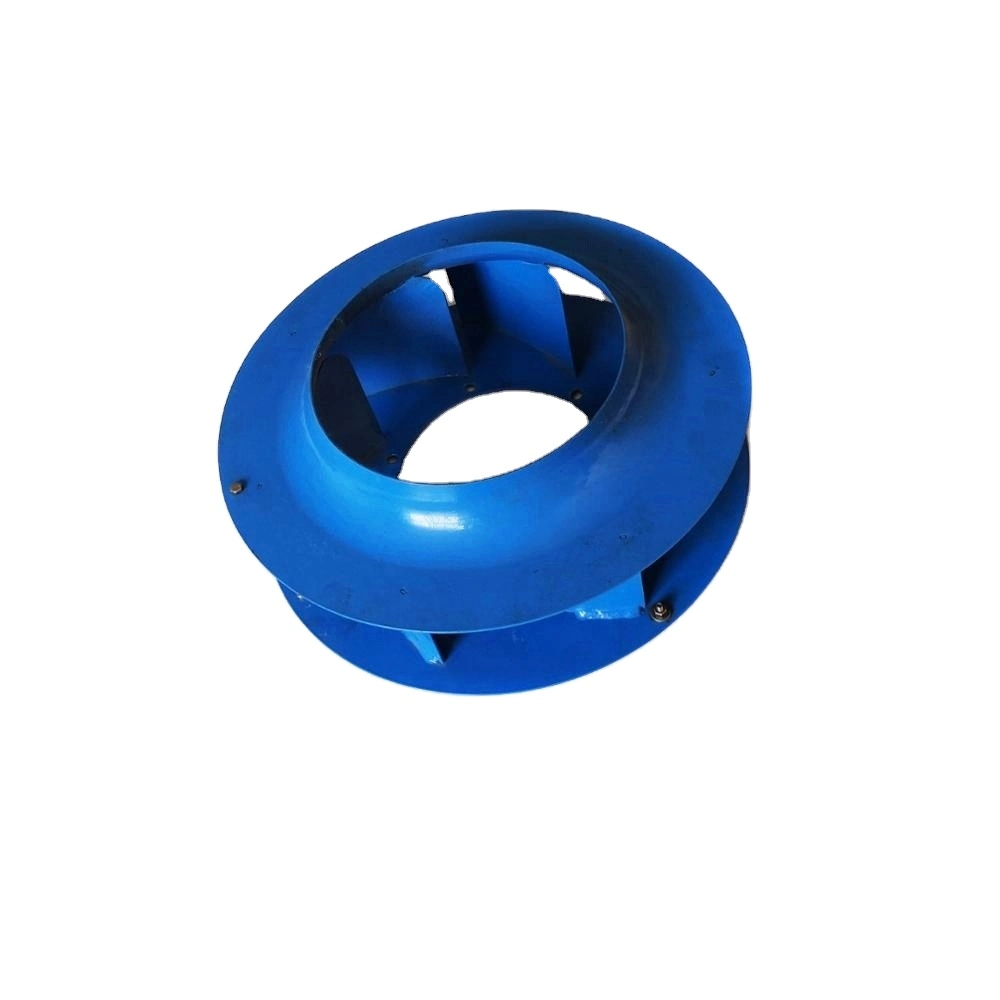

Product Name

Stamping Dies

Custom Requirement

According Customers Request

Product Material

Stainless Steel, Copper, Iron,

Size

According to Your Drawing or Our Existing P

Certification

GB/T19001-2016/ISO9001:2015

Mould Life

200,000-3,00,000shots

Transport Package

Wooden Cases or Custom Made

Trademark

Hongmaoda

Origin

Hebei, China

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

100.000kg

Product Description

Product Parameter

| Product Name | stamping die/mold/mould/tool | Drawing Format | igs,stp,prt,asm,pdf,dwg,dxf |

| Metrial | SKD11,DC53,Cr12MOV,CR12,SKD61 etc. | First Tria | 15- 25 days after mold drawing confirmed |

| Design Software | AutoCAD, PRO/E,UG,catia,Dynaform,solidworks etc. | Die Life | 1,000,000~ 3,000,000 shots |

| Die Type | stamping die,compound die,progressive die,punched hole, cutting die,deep drawn die or according to your parts | Note | The products are here to show the scope of our manufacturing capabilities and it not for sale |

Product Type

Product Description

As per customers specific requirements

or customers give us specific sample;

or customers' conceptual or preliminary design;

or customer sketched ideas.

or customers give us specific sample;

or customers' conceptual or preliminary design;

or customer sketched ideas.

Die Type

stamping die,compound die,progressive die,punched hole, cutting die,deep drawn die or according

to your parts.

to your parts.

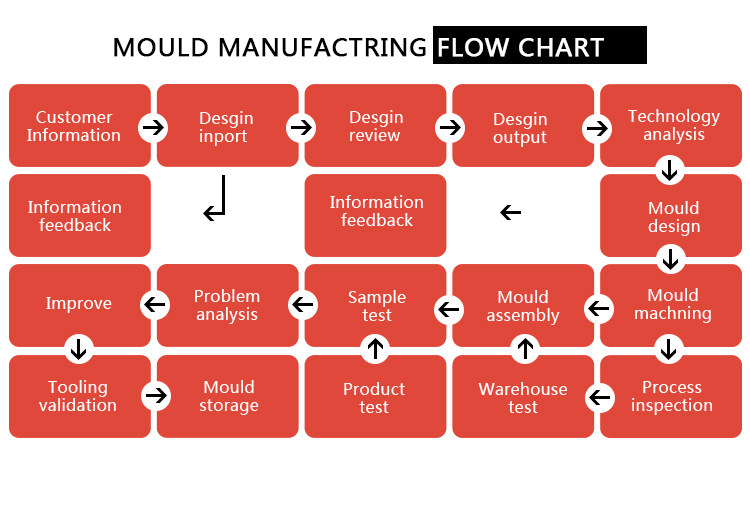

With advanced management concepts and complete processing equipments,we are a one-stop service company gatheringresearch,development,desgin,manufacture,processing and technical training. So that We have rich successful experience in making all kinds of moulds according to customer's requirements.

ONE-STEP SERVICE

1.Dessign Drawings

2. Purchasing Mould steel

3.Processing

4.Heat Treatment

5.Assembly

6. Test the mold

7.Finished

8.Package

CUSTOMER EXHIBITION

Please believe that We are your best choice.

PACKING& SHIPPING

1.Painting

2.Slushing oil

3.PE film for protecting

4.Related documents

5.Fastening

6.Plywood case

Packing & Delivery

Shipping:

For trial samples delivery:

Express--DHL ,FedEX, UPS, TNT, and so on

For die delivery:

Domestic----- by road, by air, or others

Overseas-----by air, by sea

By air around 2-5 days By sea around 15-40 davs.

Usually we use wooden cases or plywood cases for the packaging.

With rich experience in exporting we can choose reasonable packaging for you to reduce the shipping risk

Of course you Can appoint the packaging according to your requirement We can try our best to satisfy you.

PRODUCTS RECOMMENDED

ABOUT US

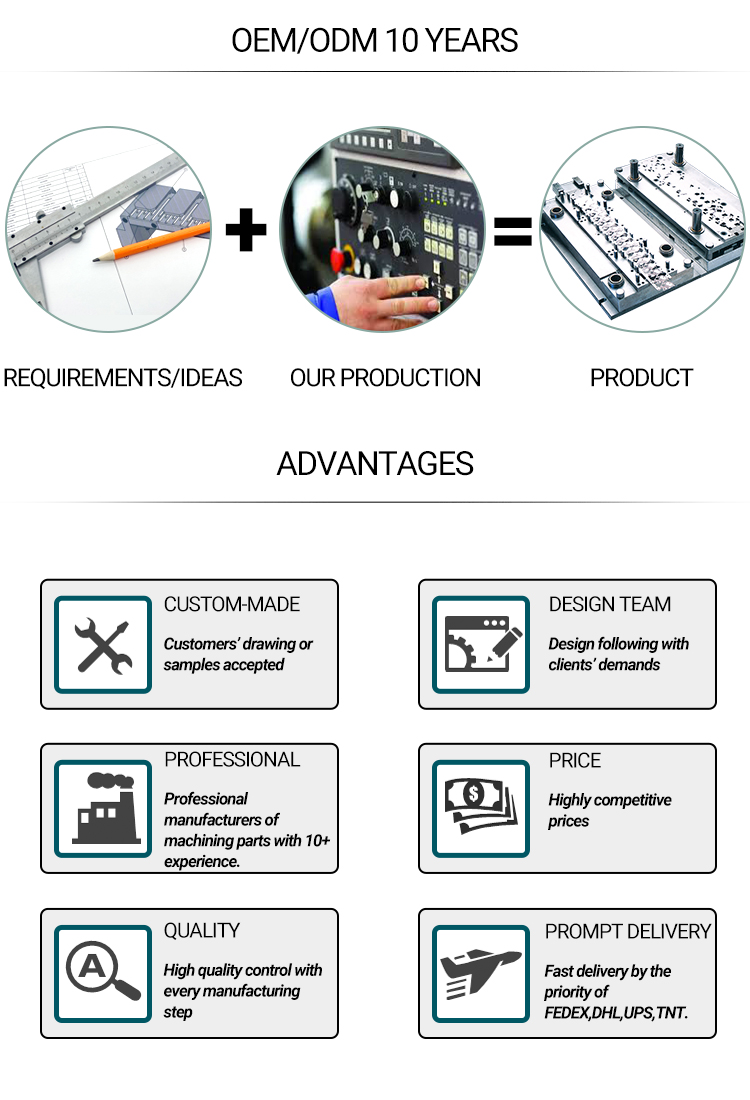

Why Choose Us

Q: Besides molds, do you generate products as well? A: Yes,we can make your projects here in our factory,But we only make it from making a new mold...then,from above new mold, making parts out of it.?We make the production job for our customers in our factory. In other words, we do not have any existing mold.?In short, we produced customized molds and products but we also provide our customers reverse engineering service. Q: How can I get the quote? A: First, we need our customers provide their technical data like 2D, 3D drawings or samples. After receiving your project, our experienced and professional team will start to study and evaluate it. During this time, our team will keep discussing with the designers to make sure that every details are clear.Finally, we will give our customers quotation reports. Q: Does your company provide design service ? A: Absolutely yes. We have helped countless customers from Europe and North American to invent their new products.Our experienced engineers give our customers useful suggestion to help them solve the problems that they encounterwhen designing and process the molds and products. Q: Why is your price so competitive ? A: First of all, what we are famous for is that we produce interchangeable core mold,which needs not only precision work but also flexible team work to adjust to what our clients really want.Also, all processing steps are carried in our factory under the supervision of our professional engineers. We appreciate that all of our customers emphasized on quality and efficiency and that's why our company wants provide too.