- Overview

- Product Description

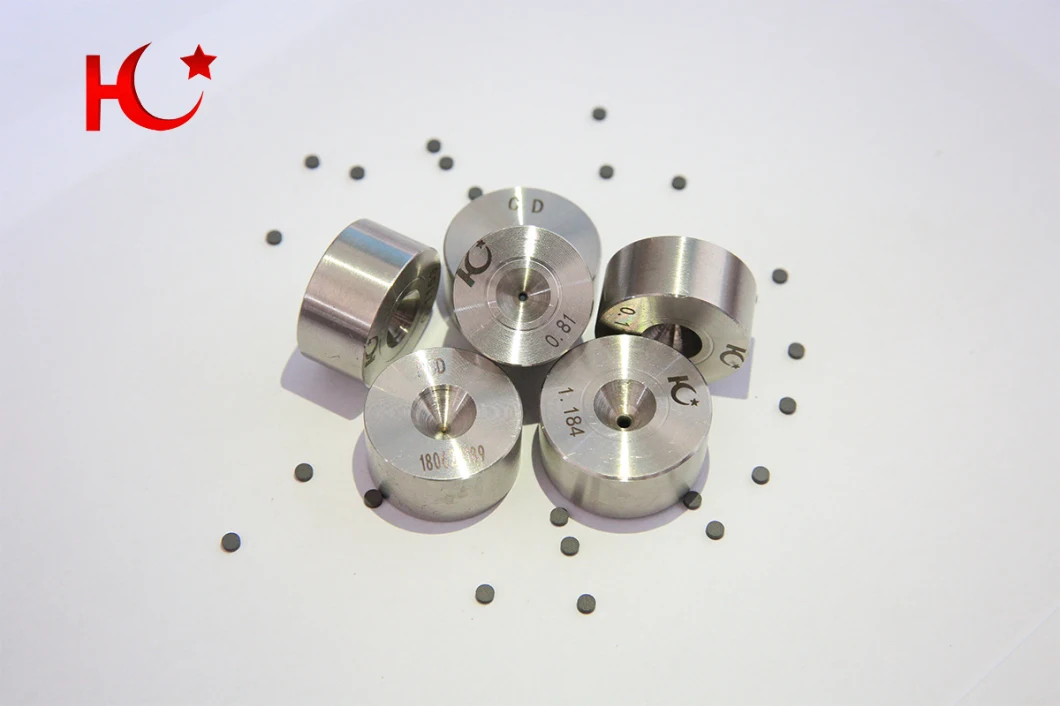

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Company Profile

- Our Advantages

- FAQ

Basic Info.

Model NO.

MONO230700

Surface Treatment

Polish

Application

Hardware, Commodity, Electronic, Car

Certification

ISO

Warranty

1 Year

Customized

Customized

Delivery Time

5-7 Days

Color

Silver Grey

Transport Package

Standard Export Packing

Specification

1kg

Trademark

Red star

Origin

Anhui, China

HS Code

82072090

Production Capacity

1000000 Pieces/Year

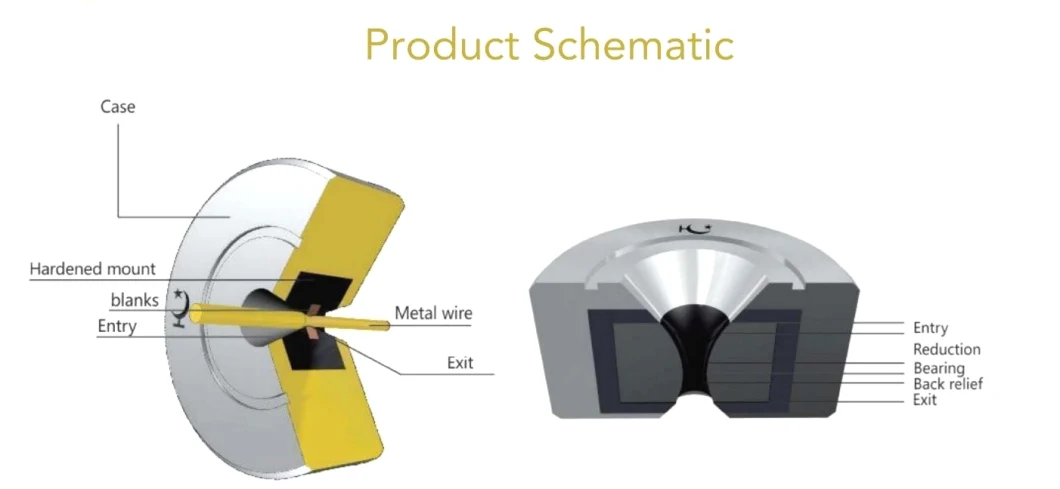

Product Description

PCD dies can be used in all wet and dry drawing processes and are ideal for long cycle production and drawing of abrasive wire as they outlast TC, SSCD and ND dies. Whilst natural diamond and tungsten carbide can be useful in some applications, PCD is an engineered material that helps to diversify products and reduce total tooling costs.

There are three main types of polycrystalline diamond blanks: non-reinforced ring, reinforced ring and thermally stabilised.

There are three main types of polycrystalline diamond blanks: non-reinforced ring, reinforced ring and thermally stabilised.

| Application scenario and standard control | ||

| For diamond wire busbar,steel cord,rubber tube wire,etc | ||

| Project | Standard | |

| D<0.1mm | D+0.3um | |

| 0.1mm≤D<0.2mm | D±0.5um | |

| Reduction Angle | 8°±1° | |

| Bearing Length | 20%-40%D | |

| Ovality | ≤0.2um | |

| Entrance /exit angle | 60°±10° | |

| Back relief | 10°±2° | |

| Concentricity | ≤15um | |

| Remark: It is recommended to use imported polycrystalline drawing die,Sumitomo 805f blanks. The above criteria are for reference | ||

Application scenario and standard control For stainless steel wire,spring wire,welding wire,etc. | ||

| Project | Standard | |

| Entrance angle | 30°±5° | |

| Reduction Angle | 14°±2° | |

| Bearing Length | 40%-80%D | |

| Ovality | ≤lum | |

| Exit angle | 50°±20° | |

| Back relief | 15°±5° | |

| Remark It is recommended to use CD die and import PCD die. The above criteria are for reference | ||

| Application scenario and standard control For enameled wire,copper wire,aluminum wire,copper clad aluminum wire,gold wire,silver wire and other non-ferrous metal wire | |

| Project | Standard |

| Entrance angle | 30°±5° |

| Reduction Angle | 16°±2° |

| Bearing Length | 20%-50%D |

| Ovality | ≤lum |

| Exit angle | 50°±20° |

| Back relief | 15°±5° |

| Remark: It is recommended to use ND die,imported PCD die and CD drawing die.It is suitable for multi head wire drawing machine The above cnteria are for reference | |

| STANDARD SPECIFICATIONS | |||

| Reduction angle and Bearing length | Soft wire products... copper wire,aluminum wire, brass wire,gold wire,etc Hard wire products... Stainless steel wire, copper lated steel wire, galvanizde steel wire. brass plated steel wire tungsten wire,etc | ||

| Reduction angle and Bearing length | Soft wire products | Hard wire products | |

| 5%-8% | 12°±2° | 8°±1° | |

| 8%-12% | 14±2° | 10°±1° | |

| 12%-16% | 16°±2° | 14°±1° | |

| 16%-25% | 20°±2° | 15°±1° | |

| 25%-35% | 23°±1° | 17°±1° | |

| Bearings length | 0.2-0.5d | 0.3-0.8d | |

| Standard configurations for other wire types also available. | |||

- Suitable for all applications from large drawing to ultramicrodrawing.

- The size of the embryo is guaranteed, and the maximum reaming size can be expected.

- Decobalt polycrystalline material can be widely used in high temperature hard wire drawing.

- The longest life material on the market today provides the highest productivity and reduces downtime.

- The unique physical characteristics of artificial polycrystalline enable the wire to ensure better roundness even in the case of mold wear.

In order to send you accurate product quotations and help you save order communication

time, please provide the following products related information when sending inquiries:

1. Type; ( PCD, TC, ND, SSCD, CVD)

2. Shape; (Round, or shaped)

3. Size; ( Hole size, case size)

4. Usage; ( Copper wire, steel wire, aluminum wire, etc;)

5. Tolerance;

6. Quantity; (Sample order and normal order)