- Overview

- Product Description

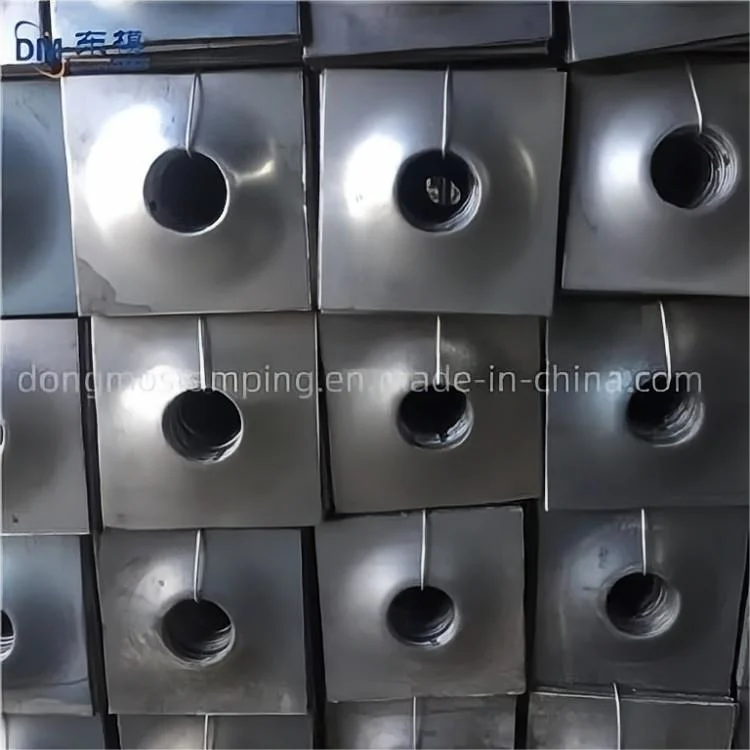

- Detailed Photos

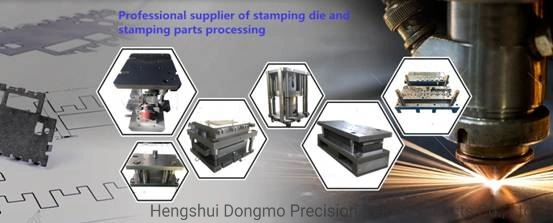

- Company Profile

- Sample display

- Certifications

- FAQ

Basic Info.

Packaging & Delivery

Product Description

The main uses and scope of application of mine bolt tray are as follows: mine bolt is a new type of bolt used for underground support of coal mine, which is made of rod body processed in a special form and equipped with resin anchoring agent, special nut and tray. The bolt has the characteristics of strong full length, intercepting length according to needs when used, simple and reliable, good anchoring performance, high strength, strong adaptability and convenient construction. It is mainly used for underground roadway support, and can also be used for engineering support in other industries.

The function of the pallet is to transfer the thrust generated by the nut locking torque to the top wall to generate the initial anchor force, and at the same time to transfer the pressure of the top wall of the roadway to the anchor rod to generate working resistance, jointly strengthen the surrounding rock and prevent the displacement of the top wall of the roadway.

| Product name | Bolt tray mold |

| Application | Mine bolt tray |

| Material | ST14-ST16S |

| Standard Parts | MISUMI |

| Template flatness | +/-0.005mm |

| Quantity | 1 set |

| Package | According to customer requirements |

| Standard | ISO9001 |

1. What information should the customer provide to get our accurate quotation?

Customer should provide relevant technical requirements, drawings, pictures, industrial voltage, planned output, etc.

2. What is the payment period?

Payment terms are 40% deposit, 60% before delivery (T/T model).

3. What is the delivery time?

Delivery time of machines is 30-60 days after receipt of deposit.

4. Do you test all the goods before delivery?

Yes, we have 100% tests before delivery.

5. Where is your factory? How do I get there?

Our factory is located in Hengshui, Hebei Province, China. Warmly welcome domestic and foreign customers

Pro patronage!

6. What material is your mold made of?

The materials are D2, YG15, DC53, SKD11, D2, SKH-9 and SKH-51

7. What is the biggest pressure in your factory?

I plant 25T, 35T, 45T, 60T, 80T, 110T, 160T punch.

8. What about the machinery in your factory?

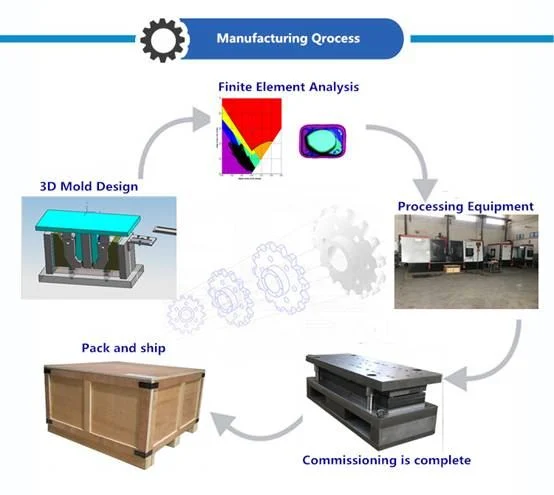

Our factory has a full set of processing equipment, including large CNC machining center, Sodic electricity Spark machining,

imported EDM-HS, radial drilling machine, milling machine, grinding machine, three-dimensional detection, etc.

9. How does your factory conduct quality control?

Quality comes first. The METS place a strong emphasis on quality control from start to finish. All molds All of these are measured

periodically by QC using three-dimensional measuring equipment.