Basic Info.

Model NO.

SWR

Transport Package

Standard Export Packaging

Specification

Variable

Trademark

SUPERIOR

Origin

China

HS Code

8477900000

Production Capacity

1000pieces/Year

Packaging & Delivery

Package Size

150.00cm * 30.00cm * 30.00cm

Package Gross Weight

30.000kg

Product Description

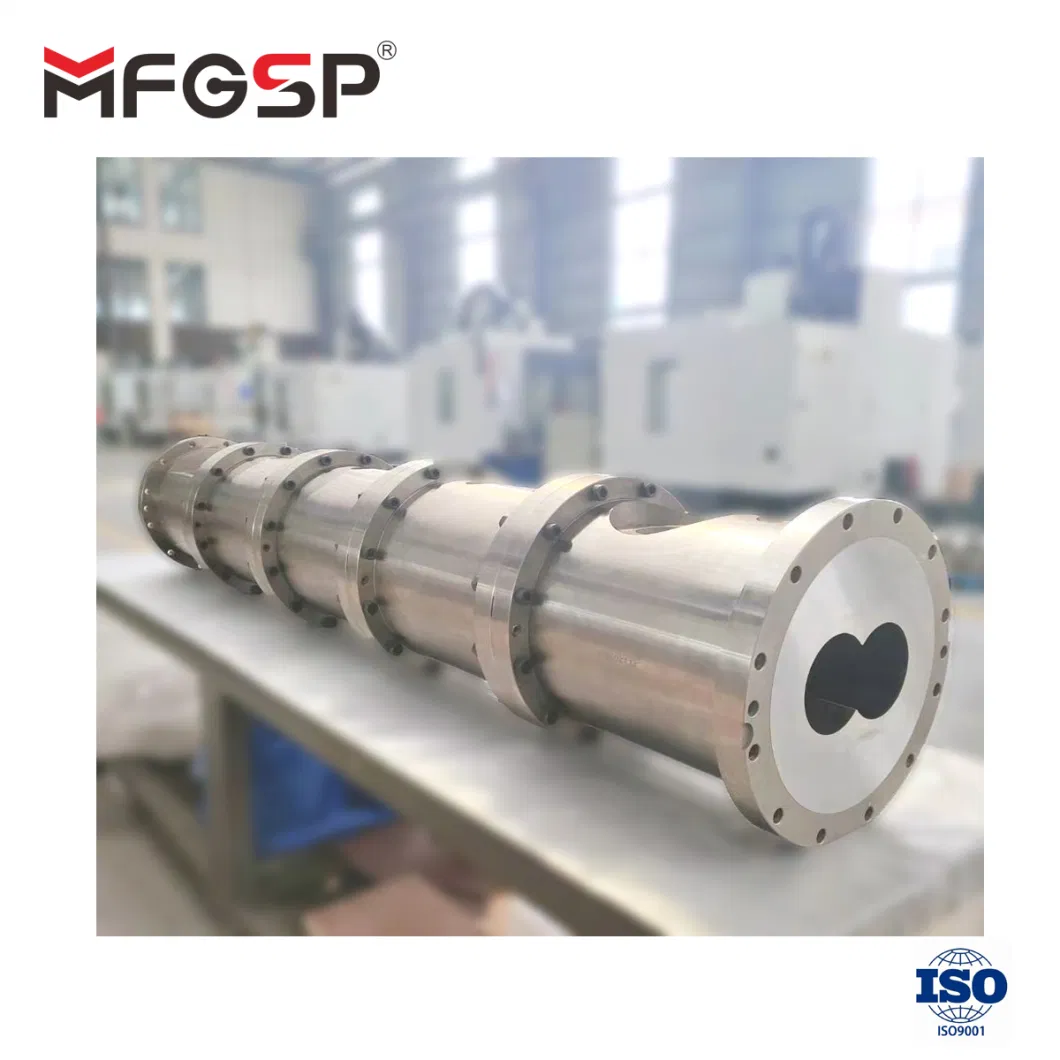

Shafts

1.We have two main kinds of shafts to meet customers' different demands:

Traditional Spline Milling Shaft

Cold rolling Shaft

2.Range of work:

Length: within 15000mm

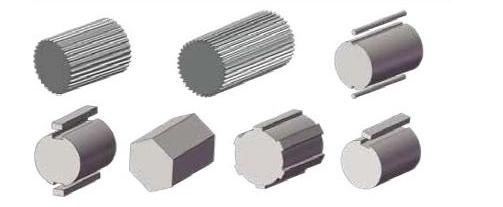

3.Keyslot Types:

Single keyway Square keyslot

High torque key button Dual keyslot

Involute inner spline Round keyslot

Rectangle spline Client's requirements available

Traditional Spline Milling Shaft

Cold rolling Shaft

2.Range of work:

Length: within 15000mm

3.Keyslot Types:

Single keyway Square keyslot

High torque key button Dual keyslot

Involute inner spline Round keyslot

Rectangle spline Client's requirements available

| Type | Contrast Content | |||||

| Machining Accuracy | Surface Finish | Mechanical Property | Spline Strength | Torque Force | Price | |

| Cold Rolling Shaft | ***** | ***** | **** | **** | **** | ******* |

| Traditional Spline Milling Shaft | *** | *** | *** | *** | *** | *** |

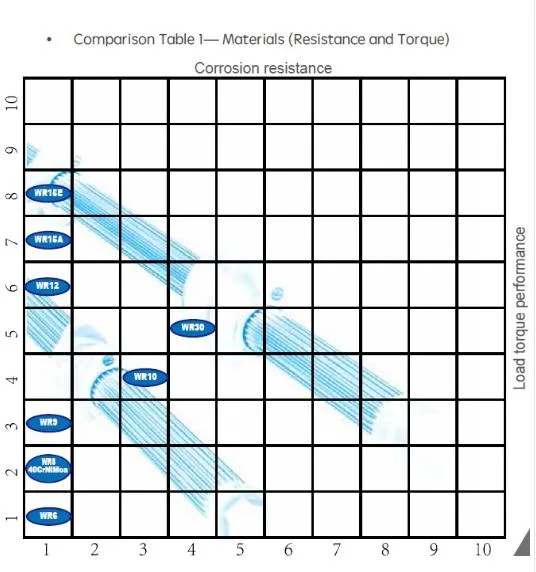

Materials

There are different materials for different demands.

- Imported material(Made in Japan or Germany)

- Domestic material

-WR series material

(WR6/WR8/WR9/WR10/WR12/WR15A/WR15E/WR30)

Advantages of cold rolling mandrel compared with traditional Spline Milling

Cold extrusion spline processing:

Replacing traditional mechanical cutting methods with advanced cold extrusion technology is a qualitative leap in the spline machining process. It not only improves the machining accuracy and surface finish, but also greatly improves the mechanical properties of the parts. The cold work hardening of the metal after cold extrusion and the formation of a reasonable fiber streamline distribution inside the part make the spline strength much higher than that processed by mechanical cutting. Through the test, the mandrel processed by the process has a load-bearing torque of 25-30%, and the accuracy is improved by two levels, achieving the national standard six-level accuracy. In addition, a reasonable cold extrusion process can form compressive stress on the surface of the part to improve fatigue strength.

| Comparison table 2--Torque of Spline Shaft | |||||||

| Type | Middle diameter of spline | Torque of spline shaft (N*m) | |||||

| WR12 HRC38 ~42 | WR15A HRC38-42 | WR15E HRC38-42 | 40CrNiMoa HRC28 ~32 | 40CrNiMoa HRC32 ~35 | 40CrNiMoa HRC3S-42 | ||

| 20 | 10.5 | 75 | 74 | 83 | 44 | 63 | 70 |

| 30 | 16 | 267 | 261 | 295 | 157 | 224 | 275 |

| 35 | 18 | 380 | 371 | 421 | 223 | 318 | 392 |

| 40 | 20 | 521 | 509 | 577 | 306 | 437 | 537 |

| 50 | 24 | 900 | 880 | 997 | 528 | 754 | 929 |

| 52 | 27 | 1282 | 1253 | 1420 | 752 | 1074 | 1322 |

| 60 | 33 | 2340 | 2287 | 2592 | 1374 | 1961 | 2414 |

| 65 | 33 | 2340 | 2287 | 2592 | 1374 | 1961 | 2414 |

| 75 | 39 | 3863 | 3775 | 4279 | 2268 | 3237 | 3985 |

| 85 | 44 | 5548 | 5421 | 6144 | 3257 | 4648 | 5722 |

| 95 | 52 | 9157 | 8948 | 10142 | 5375 | 7672 | 9445 |