- Overview

- Product Description

- Product Parameters

- Our Advantages

- Product Recommendations

- Company Profile

- Packaging & Shipping

- Payment

- FAQ

Basic Info.

Model NO.

M6-D6

Type

Tap

Material

Solid Carbide

Usage

Wood Drilling, Well Drilling, Metal Drilling, CNC Tap

Coating

Uncoated

Application

Grinding Machine

Structure

Overall Tool

Product Name

Straight Tap

Precision

High Precision

Diameter

3-20mm

HRC

45-65 HRC

Model Number

Standard

MOQ

5 Pieces

Use

Metal Tap

Total Length

48-112mm

Processing Type

Metal

Machine Type

Milling Machine

Transport Package

Plastic Box

Trademark

Seoryn

Origin

Changzhou

HS Code

8207709000

Production Capacity

2000

Packaging & Delivery

Package Size

10.00cm * 8.00cm * 6.00cm

Package Gross Weight

0.600kg

Product Description

3-20mm Carbide Straight Fluted Tap

Carbide Tap Coating Types:| Coating Type | TIN | TiAIN | As Requirement |

| Hardness(HV) | 2300 | 3000 | ~ |

| Thickness(UM) | 1 | 1~3 | ~ |

| Oxidation Temp | 500 | 900 | ~ |

| Friction Coefficient | 0.6-0.9 | 0.15-0.2 | ~ |

| Color | Golden | Black | ~ |

Carbide Tap Detailed Parameter Introduction:

| Place of Qrigin: | Jiangsu, China | Brand Name: | Seoryn |

| Model Number: | Standard | Type: | Solid Carbide Tap |

| Use: | Metal Tap | Product Name: | Straight Tap |

| Diameter: | 3-20mm | Total Length: | 48-112mm |

| MOQ: | 5 pieces | Anlge: | |

| Coating: | TiN, TiAlN | Usage: | CNC Tap |

Carbide taps have the best versatility and the strongest rigidity. Therefore, straight flute taps are generally preferred when processing materials with higher hardness and chips in the form of powder particles.

| OEM&ODM | 100% Product Qality Protection |

| 100% On-Time Delivery | Outstanding R&D Team |

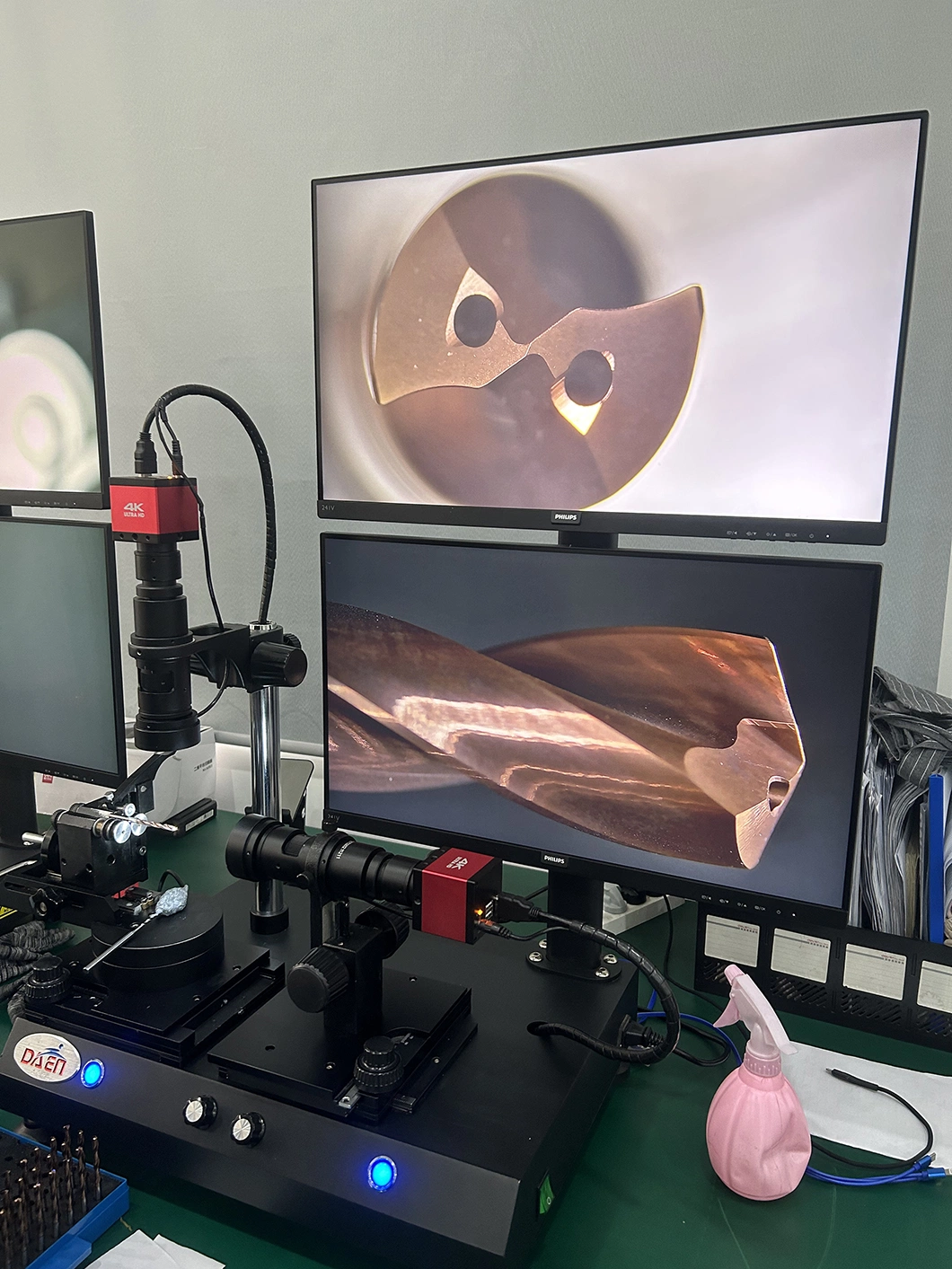

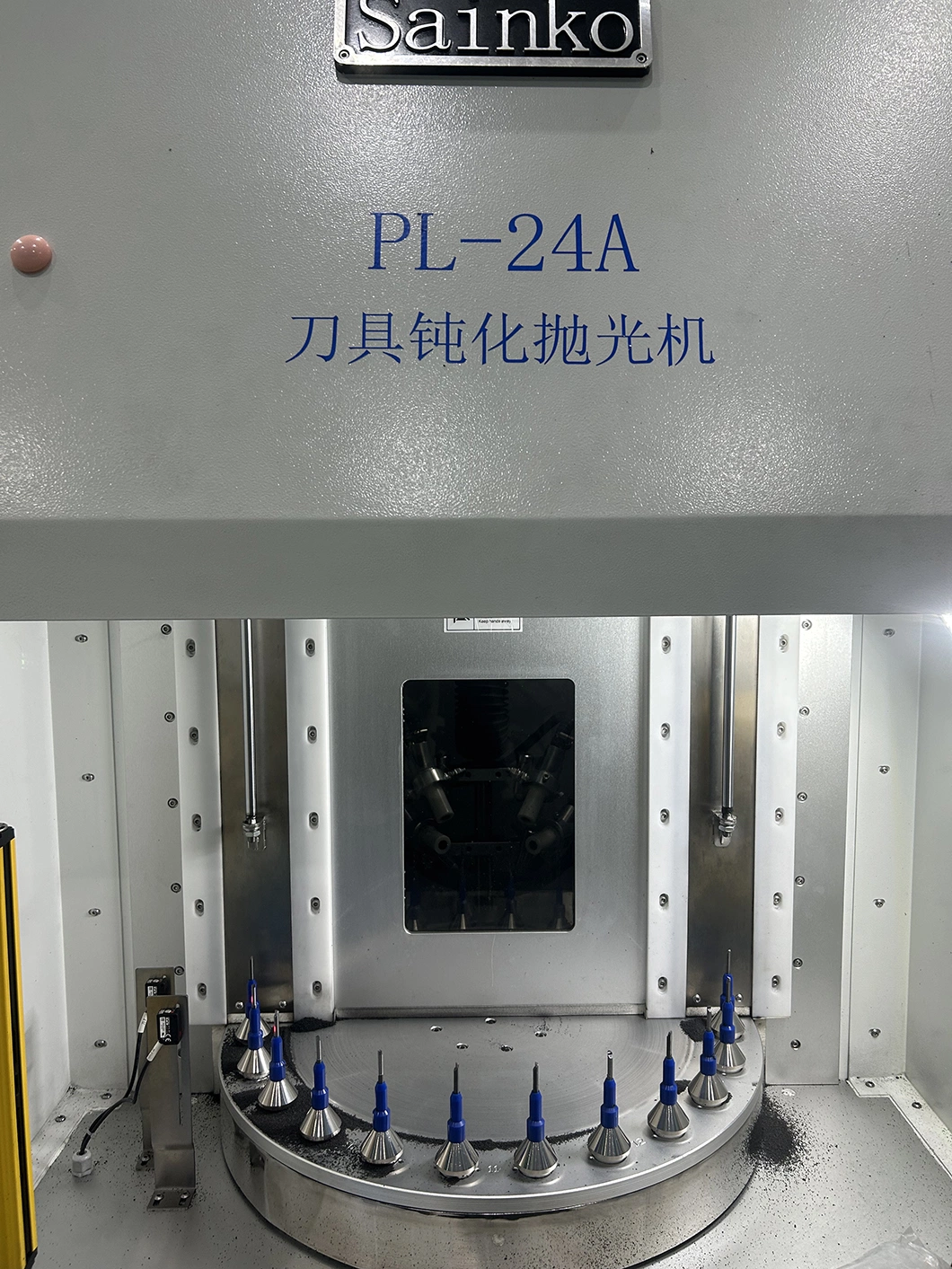

| High Precision CNC Production Line | Absolutely Strict Inspection |

Function Features

Taps are usually single or grouped. Small and medium-sized through-hole threads can be tapped at one time with a single tap.

When processing blind holes or large-size screw holes, group taps are often used, that is, more than 2 taps are used to complete the processing of a screw hole in sequence. Group taps are available in equal and unequal diameter designs.

For taps with equal diameters, each tap has a different cutting cone length; for taps with unequal diameters, each thread size is different, and only the last one has a complete tooth profile.

Taps are usually single or grouped. Small and medium-sized through-hole threads can be tapped at one time with a single tap.

When processing blind holes or large-size screw holes, group taps are often used, that is, more than 2 taps are used to complete the processing of a screw hole in sequence. Group taps are available in equal and unequal diameter designs.

For taps with equal diameters, each tap has a different cutting cone length; for taps with unequal diameters, each thread size is different, and only the last one has a complete tooth profile.

Daily Maintenance

1. When threading, the end of the workpiece should be chamfered, and the end face of the puller should be perpendicular to the axis of the workpiece; axial pressure should be applied at the beginning of threading, and the rotational pressure should be correspondingly larger; when the puller cuts out threads on the workpiece, Just stop stressing.

2. When threading, in order to break the chips and discharge them in time, the teeth should be reversed frequently.

3. The workpiece should be firmly fixed on the clips and fixtures; when the tap is broken, do not touch the broken place with your hands, but use a clip chisel or a sample punch to pick it out, and you must wear protective glasses when the tap is broken.

1. When threading, the end of the workpiece should be chamfered, and the end face of the puller should be perpendicular to the axis of the workpiece; axial pressure should be applied at the beginning of threading, and the rotational pressure should be correspondingly larger; when the puller cuts out threads on the workpiece, Just stop stressing.

2. When threading, in order to break the chips and discharge them in time, the teeth should be reversed frequently.

3. The workpiece should be firmly fixed on the clips and fixtures; when the tap is broken, do not touch the broken place with your hands, but use a clip chisel or a sample punch to pick it out, and you must wear protective glasses when the tap is broken.

Carbide tap has a complete range and is a tool for processing internal threads

Carbide tap has a complete range and is a tool for processing internal threads Changzhou SENYO Cutting Tools Co., Ltd is a high-tech enterprise not only specialized in Research and Develop, but also good at manufacturing solid carbide cutting tools and pushing them to market. For over a decade, the Company has been embracing itself with a philosophy of "Customer Foremost".

Our company has powerful technological strenght, imported high-precision machinery and Inspection equipment, including CNC grinding machines from Australia, named ANCA, also have Walter and kenner from Europe. All tremendously enhances the manufacturing capacity of the company, quality of products and competitiveness in market expansion.SENYO Cutting Tools Co., Ltd mainly process solid carbide milling cutters and boring cutter turning tools, drilling tools, special tools for PCD area, meanwhile, customized varieties of non-standard cutting tools for clients. All the products are widely applied in the area of machinery processing, like automobile. Die, Medical, Plastic and so on.

SENYO Cutting Tools Co., Ltd is always in the aim of "Survive from Quality, develop from prestige". With the best quality, the competitive price and the best attitude of service, we are confident to meet your needs.

About the payment method of cemented carbide taps

About the payment method of cemented carbide taps

1.Are you manufacturer?

We are professional manufacturer.

2. Is free shipping possible?

We don't offer free shipping service,but we will give you some discount if you buy large quantity products. And we have cooperation Express Companies,can offer you the best price of shipping cost.

3. Can you send products to our Forwarder in China?

Yes,if you have Forwarder in China,we will glad to send products to him/her.

4.Can you produce Special carbide Tools ?

Yes We can. From 2013 year. Our factory main market change from standard end mills to special tools. Special tools according to your drawing and sample.

5. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.